PlethoraOfGuns

Well-known member

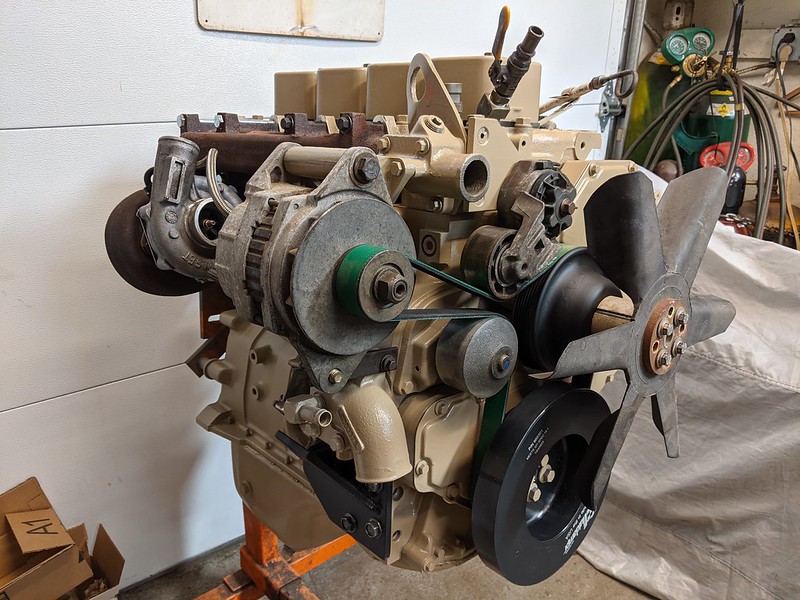

Oh geeze! That looks terrible! What vehicle is that in? In the step van, we removed the passenger seat and lifted the engine up and out through the passenger door. Plenty of room, it's great!

Enter your email address to join: