Looking at your photos I am not sure it was due to low oil. It does look like the motor has some run time (hours or miles) on it. The crank shaft throws look good and the bearings do not look like they were starved for oil to me also it is common for the top shell of the rod bearing to wear more than the bottom shell. Things to look at that will accelerate the wear on the upper bearing shells and maybe contribute to the crank shaft breakage would be your injection timing could be to far advanced, and the injector pop off values may be off. How much oil did you put in it when you changed the motor oil?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cummins Canoe (A Stepvan Story)

- Thread starter PlethoraOfGuns

- Start date

Help Support Van Living Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

PlethoraOfGuns

Well-known member

Yes, lots of miles on this engine. We agree that the oil didn't break the crank. It's just one of those things. Never changed the oil yet. It's still on it's second tank of fuel since we got it, haha. Only 5qts came out, and that engine is supposed to have 10qts. Need to get a longer dipstick tube. It's just 3/8" I.D. tube.

The new damper should balance anything else. The weight shouldn't matter, even though this thing is super heavy. People swear by it, so we're doing it for extra insurance.

The new damper should balance anything else. The weight shouldn't matter, even though this thing is super heavy. People swear by it, so we're doing it for extra insurance.

PlethoraOfGuns

Well-known member

Been very busy breaking down rest of engine and cleaning things.

[size=small]Only broke two bolts during the entire teardown process. One just happened to break flush in the head where the exhaust manifold bolts to. Drilled a hole to get an extractor in there, but then the drill bit snapped just as it broke through the opposite side![/size]

[size=small]So the next tool in my toolbox is welding a nut to the bolt. Well, that snapped off and left us back at the beginning and with welding crap all over the place.[/size]

[size=small]I didn't have any drill bits that were harder than drill bits, so we had to grind it out.[/size]

[size=small]And it was working after awhile.[/size]

[size=small]But then an hour turned into hours. And one dremmel bit turned into 10.[/size]

[size=small]But eventually we bored out the whole drill bit and old bolt, while being centered and not messing up the threads. Lots of lube and running a tap down through and good as new![/size]

[size=small]Everything else we let soak in Aerokroil for a few days and heated up before removing.[/size]

[size=small]Despite our best attempts at preventing broken bolts, one had to be dealt with.[/size]

[size=small]Didn't break flush, so we were able to grind a flat spot on it for vise grips to get her out.[/size]

[size=small]Also, what is going on with these injectors?!? Was the engine running on diesel or gunpowder?[/size]

[size=small]Only broke two bolts during the entire teardown process. One just happened to break flush in the head where the exhaust manifold bolts to. Drilled a hole to get an extractor in there, but then the drill bit snapped just as it broke through the opposite side![/size]

[size=small]So the next tool in my toolbox is welding a nut to the bolt. Well, that snapped off and left us back at the beginning and with welding crap all over the place.[/size]

[size=small]I didn't have any drill bits that were harder than drill bits, so we had to grind it out.[/size]

[size=small]And it was working after awhile.[/size]

[size=small]But then an hour turned into hours. And one dremmel bit turned into 10.[/size]

[size=small]But eventually we bored out the whole drill bit and old bolt, while being centered and not messing up the threads. Lots of lube and running a tap down through and good as new![/size]

[size=small]Everything else we let soak in Aerokroil for a few days and heated up before removing.[/size]

[size=small]Despite our best attempts at preventing broken bolts, one had to be dealt with.[/size]

[size=small]Didn't break flush, so we were able to grind a flat spot on it for vise grips to get her out.[/size]

[size=small]Also, what is going on with these injectors?!? Was the engine running on diesel or gunpowder?[/size]

When a drill bit breaks like that you can shatter it with a small spot punch. Lay a leather glove around the punch and wear safety glasses. The one time I didn’t a piece of drill bit penetrated a fellow watching safety glasses but stuck in the lens with no permanent injuries.

PlethoraOfGuns

Well-known member

Hmmm, ok. But this was 1"+ of broken drill bit in that hole. Yes, always wear protection!

$36.15

$39.90

Van Build: A complete DIY guide to designing, converting and self-building your campervan or motorhome

Amazon.com

$22.59

$24.95

The Falcon Guide to Van Life: Every Essential for Nomadic Adventures

❄ FirstSnowball

$17.00

$19.95

The Van Life Cookbook: Delicious Recipes, Simple Techniques and Easy Meal Prep for the Road Trip Lifestyle

Amazon.com

$30.59

$40.00

The Van Conversion Bible: The Ultimate Guide to Converting a Campervan

Amazon.com

PlethoraOfGuns

Well-known member

We've lost the garage!

There are tools and parts everywhere! Still have plenty to do while we wait for some engine block and head machining to be done. The torque wrench is sitting in the drawer waiting patiently for reassembly...

There are tools and parts everywhere! Still have plenty to do while we wait for some engine block and head machining to be done. The torque wrench is sitting in the drawer waiting patiently for reassembly...

nature lover

Well-known member

That sure looks familiar.

PlethoraOfGuns

Well-known member

No worries. All those parts have been cleaned and labeled. Well except for the old crankshaft and accesories. We get to keep that! All that fancy engine machining and checking and decking and stuff is beyond me. Better to let a shop do what they do.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

^^^ Hard to line bore the mains without them. Not an expensive option but extra insurance.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

Freelander

Well-known member

- Joined

- Sep 21, 2020

- Messages

- 1,132

- Reaction score

- 212

That motor doesn't have liners does it?

PlethoraOfGuns

Well-known member

In stock form, no. But if a cylinder gets damaged, they can line them. I don't believe we'll have any liners or sleeves going on.

PlethoraOfGuns

Well-known member

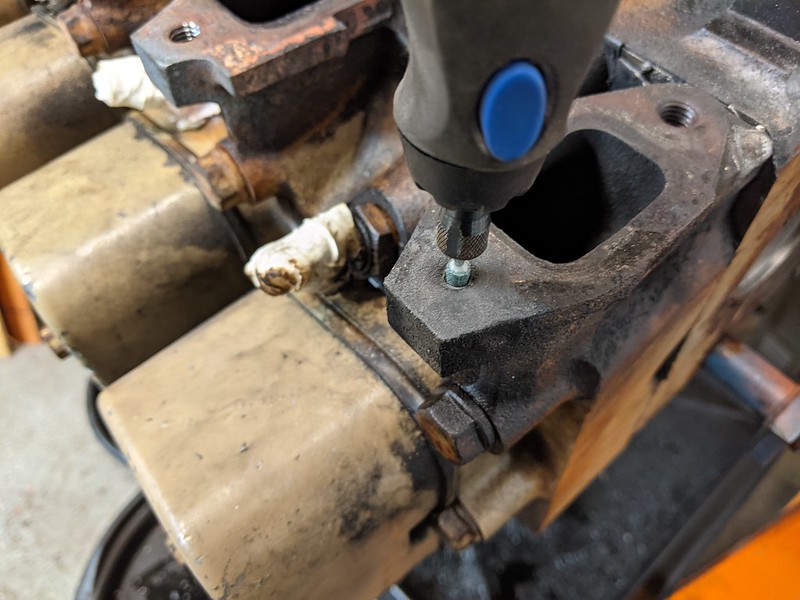

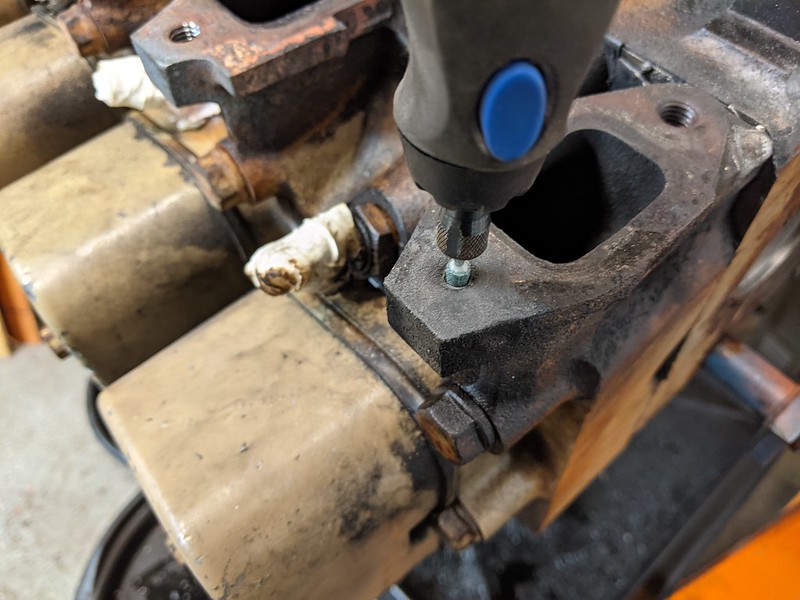

Oh boy, almost forgot to show everyone this one bolt we had to reach. It was at a crazy funny angle to loosen...

[size=small]Always make sure to carry a swivel or two.[/size]

[size=small]Don't forget a few extensions in your toolbox.[/size]

[size=small]Oh yes and wobblehead extensions are great to have too.[/size]

[size=small]Dang that thing was a pain in the dingus...[/size]

[size=small]Always make sure to carry a swivel or two.[/size]

[size=small]Don't forget a few extensions in your toolbox.[/size]

[size=small]Oh yes and wobblehead extensions are great to have too.[/size]

[size=small]Dang that thing was a pain in the dingus...[/size]

You jest but the upper bell housing bolt on older SL Mercedes required three wobble head extensions and ball socket attached to a heavy duty impact as it had to drop over the governor housing of the transmission which meant you started with a 3’ extension at the rear of the transmission and guided it in with a long skinny screw driver. You had to wrap the jointed socket with electrical tape to keep it from flopping down before you could feel it go on the head of the bolt. As soon as you felt it go on you pulled the trigger on the impact and hoped the extensions and socket didn’t come flying out at you or crack the transmission case. There is a better way to remove it but it took several more hours of labor. Don’t miss the flat rate system at all! Lol!!!

PlethoraOfGuns

Well-known member

In all seriousness, if it takes more than one universal swivel, I'm not going to own such a monstrosity. Mercedes sound terrible to work on.

Hey, don't knock the 6 in 1. I used to carry one in my tool belt at work. Was great until I really started to need a flathead to use as pry bar or chisel. Now I've lost count on how many screwdrivers I own, haha.

Hey, don't knock the 6 in 1. I used to carry one in my tool belt at work. Was great until I really started to need a flathead to use as pry bar or chisel. Now I've lost count on how many screwdrivers I own, haha.

PlethoraOfGuns

Well-known member

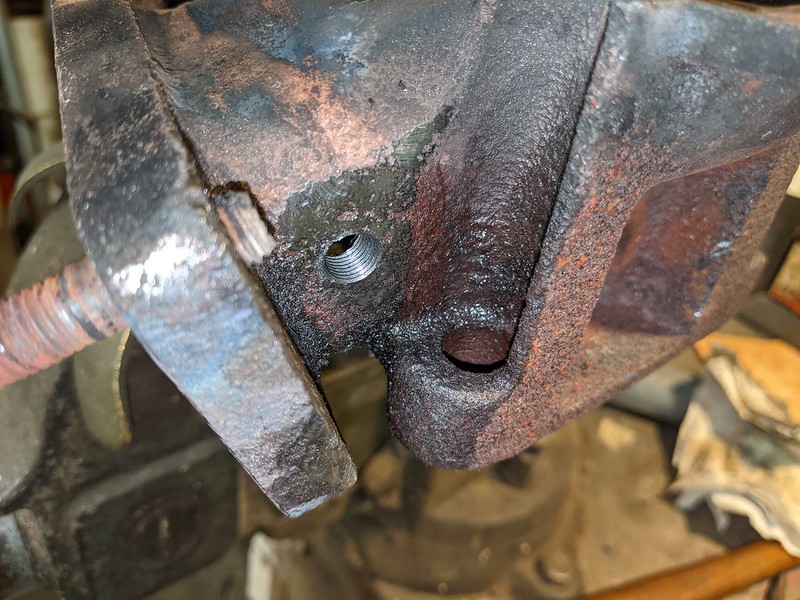

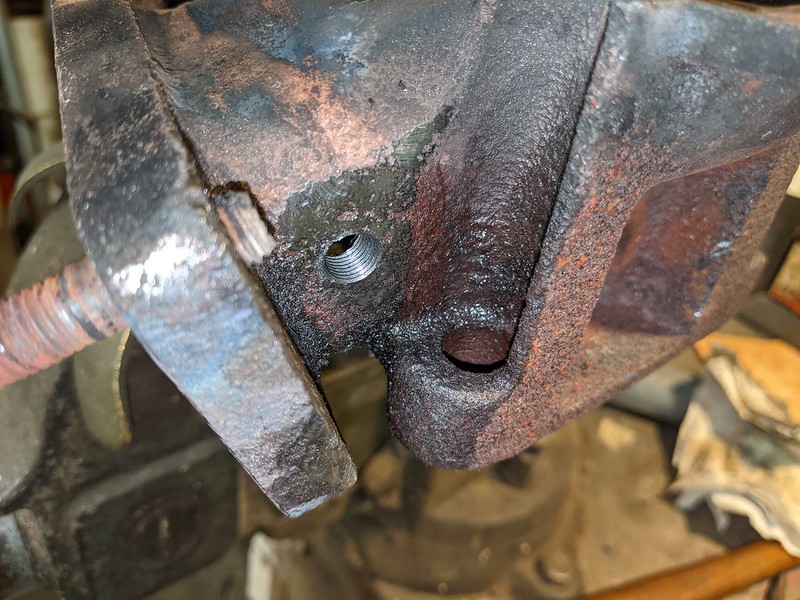

Plenty still to do.

[size=small]Found a good spot to install a pyrometer. Keeping track of exhaust temperature is a great idea to make sure nothing bad is happening.[/size]

[size=small]The exhaust manifold is pretty thick.[/size]

[size=small]So much easier to do this with the engine out of the vehicle and the manifold in a vise.[/size]

[size=small]Found a good spot to install a pyrometer. Keeping track of exhaust temperature is a great idea to make sure nothing bad is happening.[/size]

[size=small]The exhaust manifold is pretty thick.[/size]

[size=small]So much easier to do this with the engine out of the vehicle and the manifold in a vise.[/size]

Freelander

Well-known member

- Joined

- Sep 21, 2020

- Messages

- 1,132

- Reaction score

- 212

You should've installed that in the exhaust pipe after the turbo. It the tip of the pyrometer breaks off it will damage the turbo, also I believe the exhaust gases are hotter after the it lefts the turbo.

Similar threads

- Replies

- 12

- Views

- 3K