PlethoraOfGuns

Well-known member

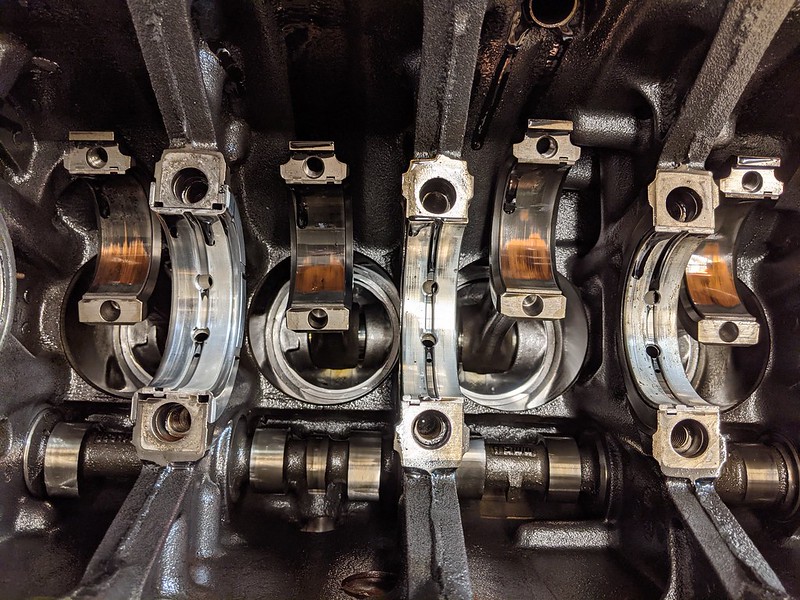

Super glue might not hold. We're going to use JB Weld, much stronger. Replacing crankshaft is a bit out of budget. Actually, all this is. We're gonna do what we can with what we got.

Haha, space heaters? These girls are tougher than I am! You should have seen how insulted they were when I offer them gloves to work with!

Haha, space heaters? These girls are tougher than I am! You should have seen how insulted they were when I offer them gloves to work with!