PlethoraOfGuns

Well-known member

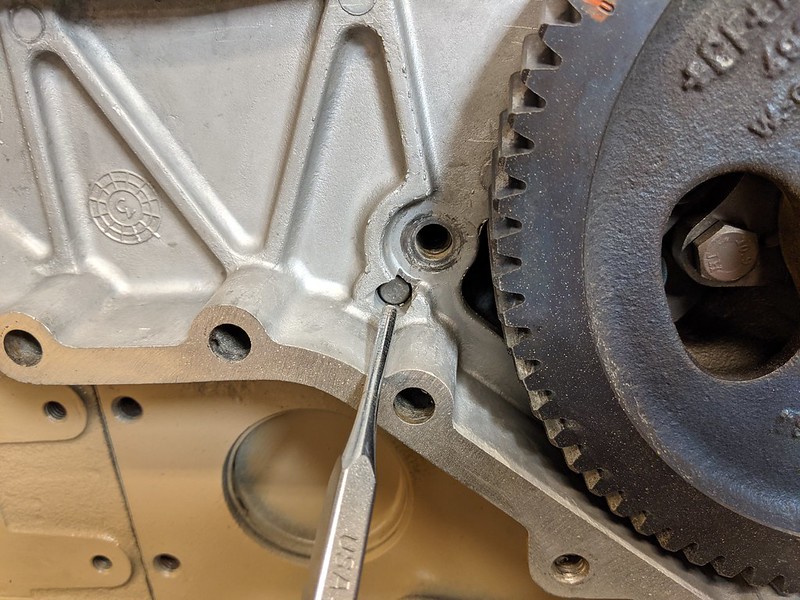

Oh no, the debate about pyrometers being pre or post turbo! I have never heard of a pyrometer tip breaking off. They are extremely durable stainless steel. Only way you could have an issue is if someone intentionally sabotaged it or it got too hot and melted off. And if your engine got hot enough to melt your pyrometer tip, your engine and turbo are already torched. Also, when you install pyrometer, give it just the tip. Don't go all willy billy and shove the whole thing in.

Exhaust gasses cool down significantly once it passed through the turbo. How much cooler? You can't guesstimate such a number to be exact, too many variables involved. Most say 300 degree drop, but it could be as high as 600.

Exhaust gasses cool down significantly once it passed through the turbo. How much cooler? You can't guesstimate such a number to be exact, too many variables involved. Most say 300 degree drop, but it could be as high as 600.