You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cummins Canoe (A Stepvan Story)

- Thread starter PlethoraOfGuns

- Start date

Help Support Van Living Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

Looks like it will be rpming soon.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

PlethoraOfGuns

Well-known member

Keeping track of rpm is as important as egt, boost, oil pressure, and coolant temp. Gotta keep this engine within healthy parameters! Still lots to do. Gotta find a place to install all these gauges...

On my son’s race car he always looked at the gauges after it was too late. I ended up installing additional idiot light sensors as well as a truckers bright red skull clearance light right in his line of sight with the words “TURN ENGINE OFF” painted below it. When it came on you could see it from the pits.

PlethoraOfGuns

Well-known member

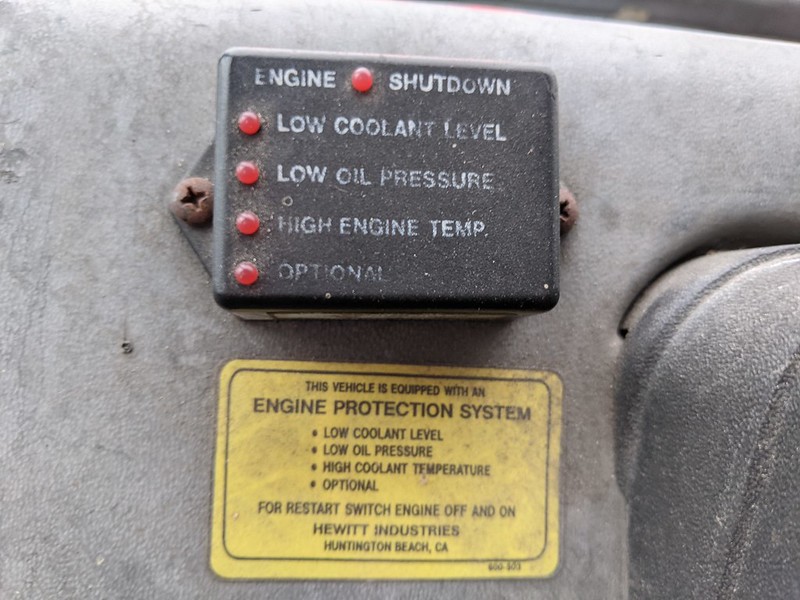

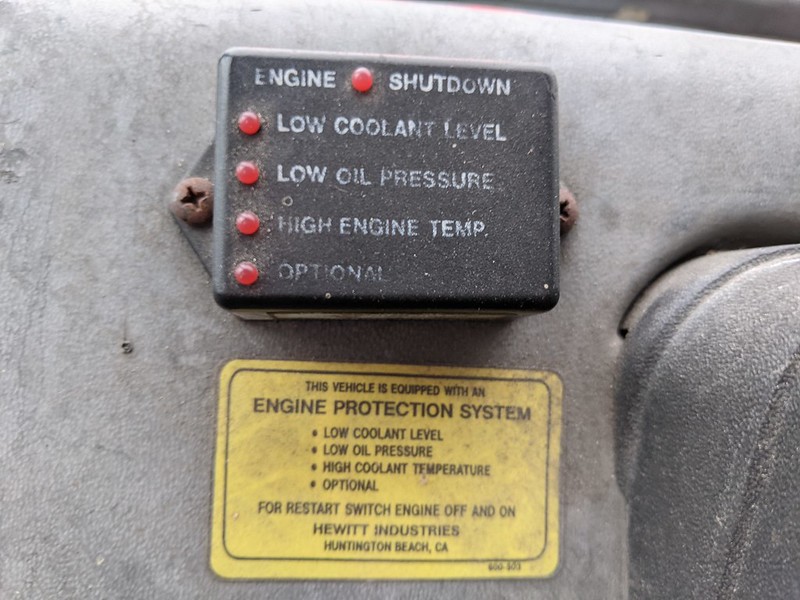

Oh, I can imagine how bad looking at the gauges too late can be. But when racing, there is probably so much going on, easy to miss. I'd install idiot lights and idiot buzzers. But you can see it from the pits, haha. What's nice about this step van is that there is an audible/visual engine warning management system. It lights and buzzes when bad things happen like over temp and loss of oil pressure. It seems to be aftermarket thing the bakery company did and I know first hand that it works. With that system I probably don't need actual gauges, but I like to monitor things accurately. Now we'll have gauges for speed, fuel level, voltage, coolant temp, oil pressure, fuel pressure, boost pressure, exhaust temperature, and engine rpm.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

Just wondering if the shift noid light on a race tach adjusts down to 25-2700 rpms.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

^^^Are you insinuating someone might be prone to over rev? Lol !!! Honest dad the crank just broke! Lol !!! Fond memories. Kentucky boys tend to test limits, heck I blew up my grandpas rototiller motor cause I wired the governor wide open before I was ten! I learned a long time ago to build it right and let her go. Gauges are more for trouble shooting for me now a days. My nose, ears, fingers and eyes do a pretty good job of telling me something is wrong.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

Yeah, I've got solid lifters in my old shovelhead and no tach. My back side tells me when its time to shift.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

All the diesels I have worked on had gov built in the fuel system whether it was springs or the computer pulling fuel away from it but always some type of fuel limit. The runaway diesels are due to the motors pulling oil in the cylinders. On a side note I did stall one out on a hill and it fired back up running backwards but no damage shut it down pretty quickly.

Freelander

Well-known member

- Joined

- Sep 21, 2020

- Messages

- 1,132

- Reaction score

- 212

Or a Detroit Diesel with a rack that wasn't adjusted probably.

Yep seen that also we would have vise grips on the rack so you could pull them back if it stuck open. But i have heard of some of them after sitting an injector can get sticky and hold the rack wide open but my experience tho it be limited on the two strokes was a bad adjustment.

highdesertranger

R.I.P HDR

- Joined

- Apr 4, 2012

- Messages

- 22,892

- Reaction score

- 92

Ah yeah a good ole Screaming Jimmy. Highdesertranger

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

Yep, got one semi hauling grain by the house (on the main highway) that has a jimmy. You sure can pick it out from the rest. Used to drive a dumptruck years ago with a Cummins 903 that sounded close. Now back to our normal programming.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

PlethoraOfGuns

Well-known member

Nothing beats a good running 2 stroke diesel! But yes, back to the normal programming.

Before I forget, this is the aftermarket engine warning management system. It buzzers and flashes at you when **** hits the fan.

Before I forget, this is the aftermarket engine warning management system. It buzzers and flashes at you when **** hits the fan.

highdesertranger

R.I.P HDR

- Joined

- Apr 4, 2012

- Messages

- 22,892

- Reaction score

- 92

That Hewitt Industries is right by me. Well at least for the next 12 hours as I am heading to Arizona. Highdesertranger

PlethoraOfGuns

Well-known member

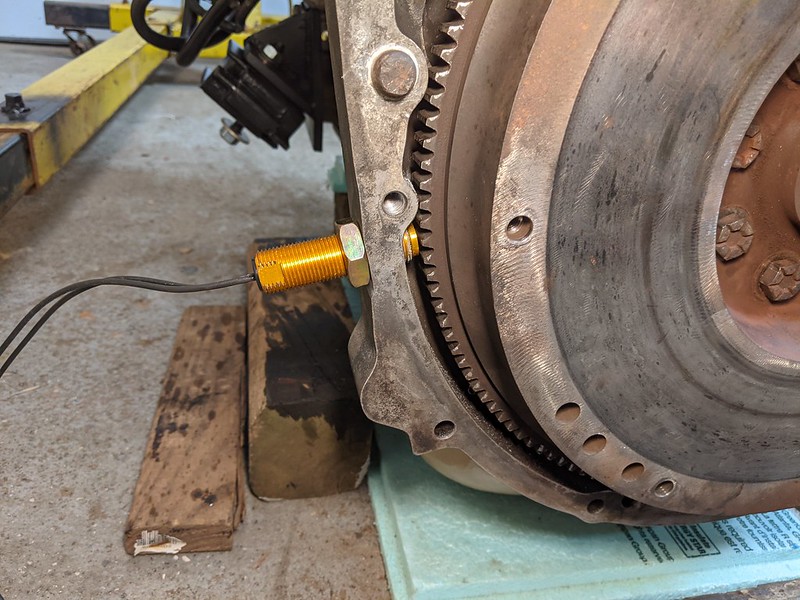

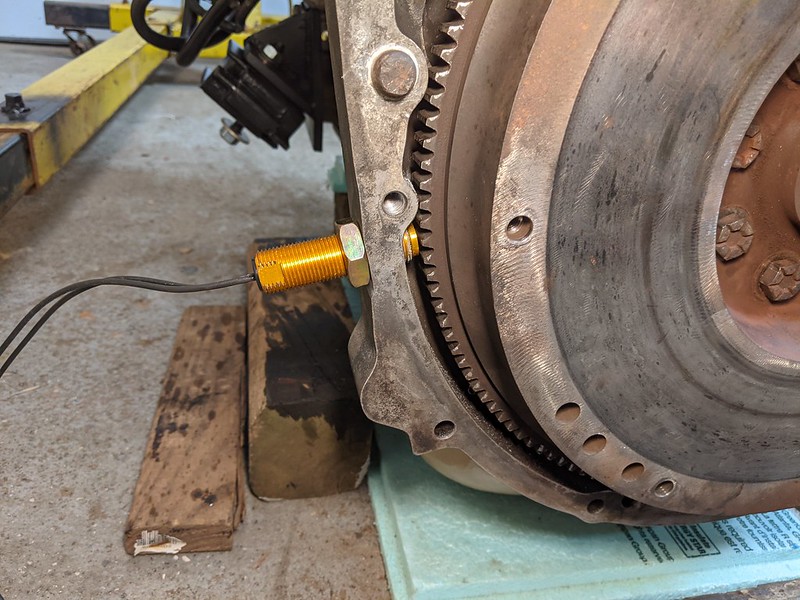

Project tachometer is complete.

[size=small]Got the flywheel mounted and took some careful measurements. Removed everything and applied those measurements.[/size]

Luckily we had a 3/4"-16 tap laying around for the magnetic pickup sensor.

Got plenty of threads to hold sensor tight. Even ground the bell housing adapter so the lock down nut sits flat.

Got the clutch aligned and torqued down. Looks like we're all ready to install in the van. Just need to add filters, fill lines, prime some stuff and she should fire right up! Hopefully we'll have an easier time priming with the piston lift pump, because the old diaphragm lift pump was terrible.

[size=small]Got the flywheel mounted and took some careful measurements. Removed everything and applied those measurements.[/size]

Luckily we had a 3/4"-16 tap laying around for the magnetic pickup sensor.

Got plenty of threads to hold sensor tight. Even ground the bell housing adapter so the lock down nut sits flat.

Got the clutch aligned and torqued down. Looks like we're all ready to install in the van. Just need to add filters, fill lines, prime some stuff and she should fire right up! Hopefully we'll have an easier time priming with the piston lift pump, because the old diaphragm lift pump was terrible.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

What triggers it? Must be something attached to the flywheel. Maybe I missed it. How about some gauges to complement the idiot light management system? Idiot lights are good if they work right especially with buzzers.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

PlethoraOfGuns

Well-known member

The magnetic pickup sensor detects the magnetic variations between the teeth and sends signals to the tach gauge. On the back of the tach gauge there are dip switches to program how many teeth it's supposed to count. Yes, we are installing actual gauges.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

I kept picturing a "reflector" of some sort on the flywheel. Schooled an old dog. I'm looking forward to it rolling coal again. [emoji106]

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

highdesertranger

R.I.P HDR

- Joined

- Apr 4, 2012

- Messages

- 22,892

- Reaction score

- 92

Looking good. Highdesertranger

Similar threads

- Replies

- 12

- Views

- 3K