Never had much luck with it but if I remember right preheating the cast iron made a big difference. I had pretty good luck where I could drill and tap tempered set screws starting at one end of the crack and overlapping the previous screw till I reached the end of the crack. Good luck!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cummins Canoe (A Stepvan Story)

- Thread starter PlethoraOfGuns

- Start date

Help Support Van Living Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

PlethoraOfGuns

Well-known member

Preheating is needed if welding cast iron. But I think if you're brazing you can get away without preheating, especially if you're doing localized TIG brazing. But I'm no expert, so we'll see what happens. I've heard of the screw technique. Cast iron is just a terrible material all together.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

I think the preheating was more for burning off contaminants, oil etc. Only seen it done once and he peened the weld with a ball peen hammer to condense the weld, I'm assuming. With your situation maybe tapping with a body pick hammer. Just my $.02. Good luck.

Sent from my SM-T560NU using Tapatalk

Sent from my SM-T560NU using Tapatalk

PlethoraOfGuns

Well-known member

Hmmm, preheating will clear the crack and area of any remnants of coolant. Good idea! I can easily get a lil bit of torch on the area around the crack.

scottrod31

Well-known member

- Joined

- Aug 31, 2012

- Messages

- 67

- Reaction score

- 41

What ever happened with your repair?

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

Yes, inquiring minds want to know.

Sent from my SM-T220 using Tapatalk

Sent from my SM-T220 using Tapatalk

$14.99

$29.99

OXSUN Portable Solar Panel,14W ETFE Solar Panel with Dual USB QC3.0 Foldable and Waterproof for Smart Phone, Camping Lanterns and Small Fans Monitor

Genneng Innovations

$50.49

$67.49

Amazon Basics 173-Piece General Household Home Repair Mechanic's Hand Tool Set with Storage Case, Portable for DIY

Amazon.com

$30.59

$40.00

The Van Conversion Bible: The Ultimate Guide to Converting a Campervan

Amazon.com

$22.27

$23.95

Van Life Cookbook: The portable, budget-friendly and sustainable cookbook for life on the go

Amazon.com

$25.99 ($0.29 / Ounce)

Gas One 6 Hour Chafing Fuel - Food Warmer for Chafing Dish Buffet Set - Liquid Safe Fuel With Wick & Lid Opener 7.4 Oz (Pack of 12)

Amazon.com

PlethoraOfGuns

Well-known member

Sorry everyone. I've been trying to stall the welding repair. Very nervous about screwing it up. Been working in the meantime to build up some funding in case this whole thing goes south.

PlethoraOfGuns

Well-known member

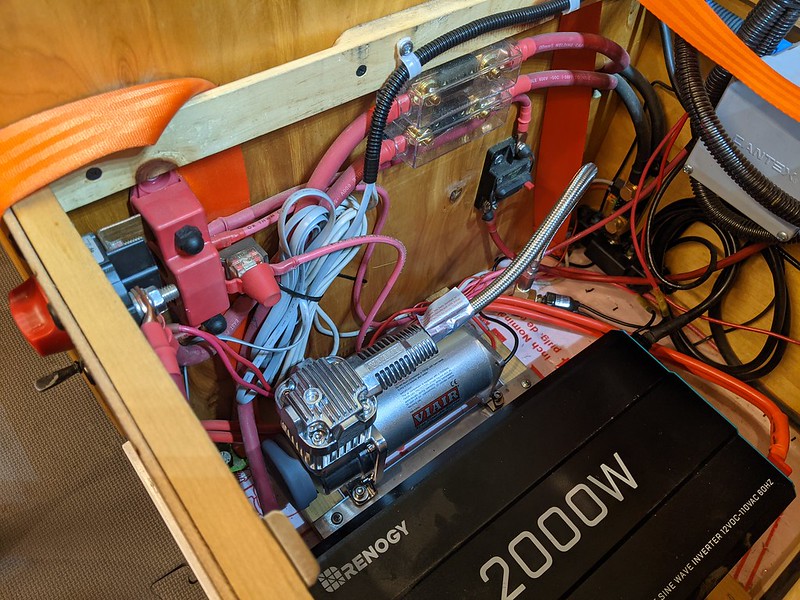

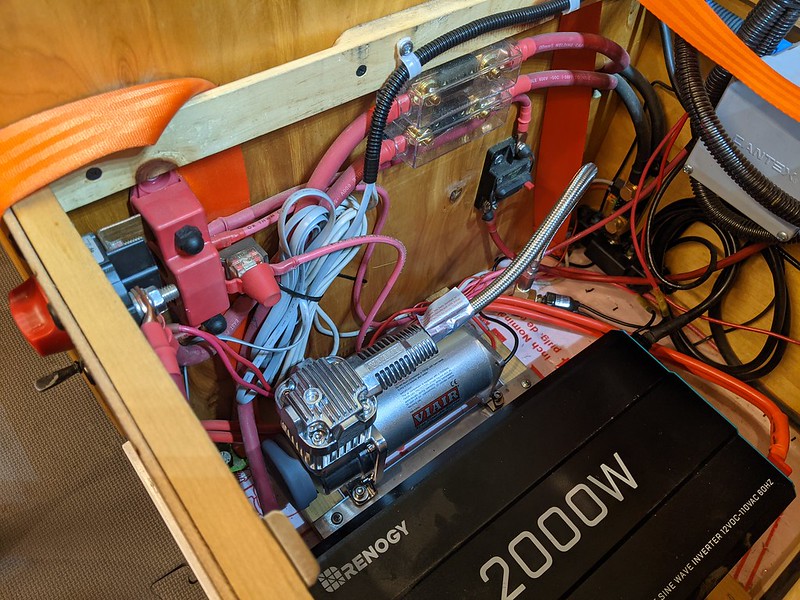

While I stall on fixing the cracked engine, decided to get the air compressor up and running. Got this thing ages ago, just never had time to install it.

First step was to mount air tank. Found this 5 gallon tank floating around in a dumpster. Welded up brackets from the scrap bin and we got a good tank to mount under the rig.

Mounted tank down behind the driver seat. 5 gallons should be plenty good for all the small stuff we'll be using it for.

Mounted the compressor nice and close to the battery. Put a toggle switch on outside of electrical cabinet by the battery cutoff switch. Piping goes to check valve and then through bulkhead fitting down to the tank.

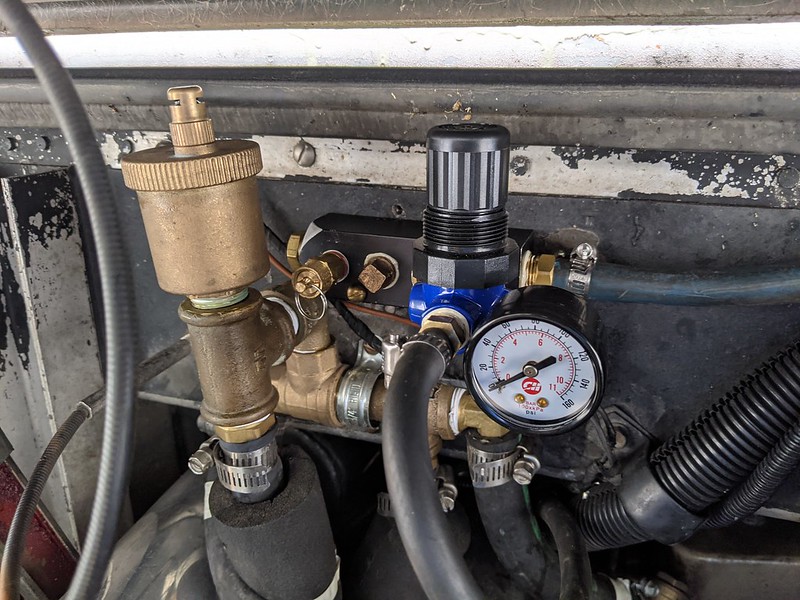

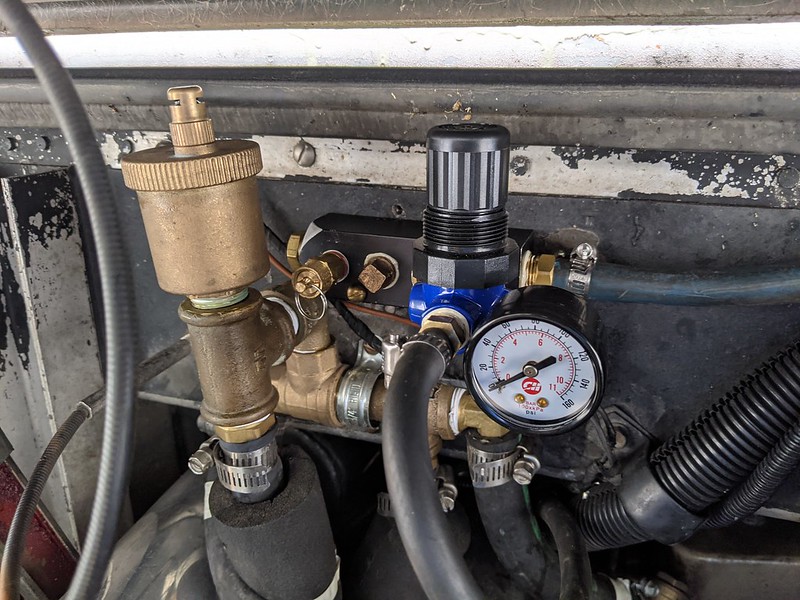

On the firewall I installed this manifold with all kinds of other goodies.

On the passenger seat I installed a connector to hook up and air hose. Now we can easily air up tires and such!

First step was to mount air tank. Found this 5 gallon tank floating around in a dumpster. Welded up brackets from the scrap bin and we got a good tank to mount under the rig.

Mounted tank down behind the driver seat. 5 gallons should be plenty good for all the small stuff we'll be using it for.

Mounted the compressor nice and close to the battery. Put a toggle switch on outside of electrical cabinet by the battery cutoff switch. Piping goes to check valve and then through bulkhead fitting down to the tank.

On the firewall I installed this manifold with all kinds of other goodies.

On the passenger seat I installed a connector to hook up and air hose. Now we can easily air up tires and such!

PlethoraOfGuns

Well-known member

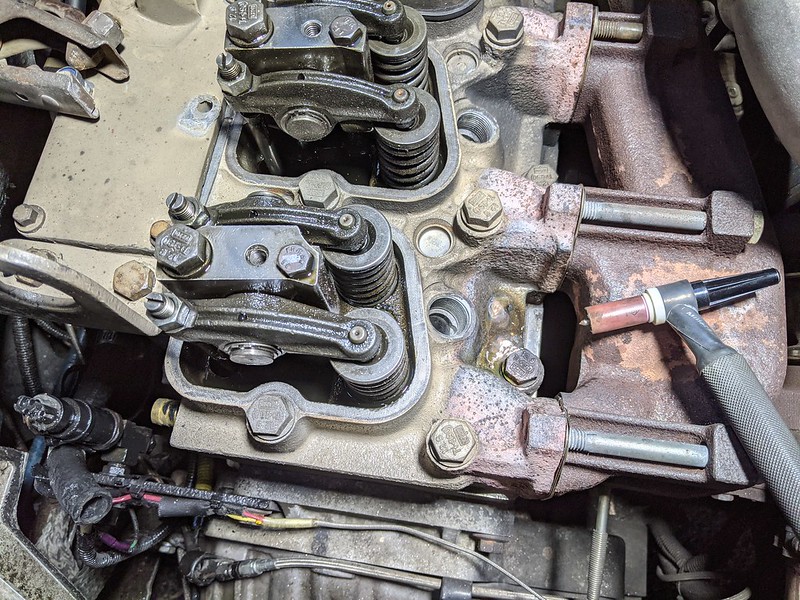

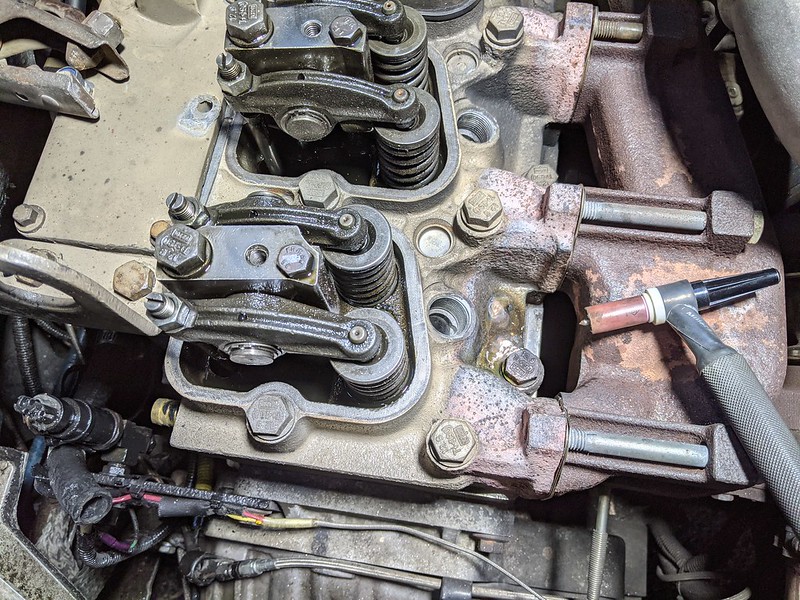

Finally got around to attempting the fix on this cylinder head repair. While the coolant is all drained, I'm also re-plumbing the crazy coolant/aux heat/block heat/Espar system. So it will be a few more days before we fire the engine up.

I think I did it as best as one could. We'll see what happens when we put coolant back in and fire it up.

But I'm not sure I 100% trust the whole brazing thing. And since JB Weld is holding the crankshaft together, I figured why wouldn't it work here? So I gooped a thin layer over the whole braze job. Figured it couldn't hurt.

I think I did it as best as one could. We'll see what happens when we put coolant back in and fire it up.

But I'm not sure I 100% trust the whole brazing thing. And since JB Weld is holding the crankshaft together, I figured why wouldn't it work here? So I gooped a thin layer over the whole braze job. Figured it couldn't hurt.

mudbunny

Well-known member

- Joined

- Mar 4, 2016

- Messages

- 148

- Reaction score

- 13

Here's hoping it's the cure. Cast iron welding has gotten to be a lost art in this disposable world.

angelmander

Member

- Joined

- Jul 17, 2019

- Messages

- 19

- Reaction score

- 1

You’re a pretty handy dude. I like that. I’m also a welder and I have a 2001 MT55 freight liner stepvan with a Cummins 5.9 under the hood. I can’t believe I found another guy like me

PlethoraOfGuns

Well-known member

Agreed. So many things can be fixed and be good as new. But cast iron is a crap shoot. we'll see what happens.Here's hoping it's the cure. Cast iron welding has gotten to be a lost art in this disposable world.

Oh no way! Step vans are the best! Do you have a build thread somewhere? I'm always looking to see what other creative things people do.You’re a pretty handy dude. I like that. I’m also a welder and I have a 2001 MT55 freight liner stepvan with a Cummins 5.9 under the hood. I can’t believe I found another guy like me

PlethoraOfGuns

Well-known member

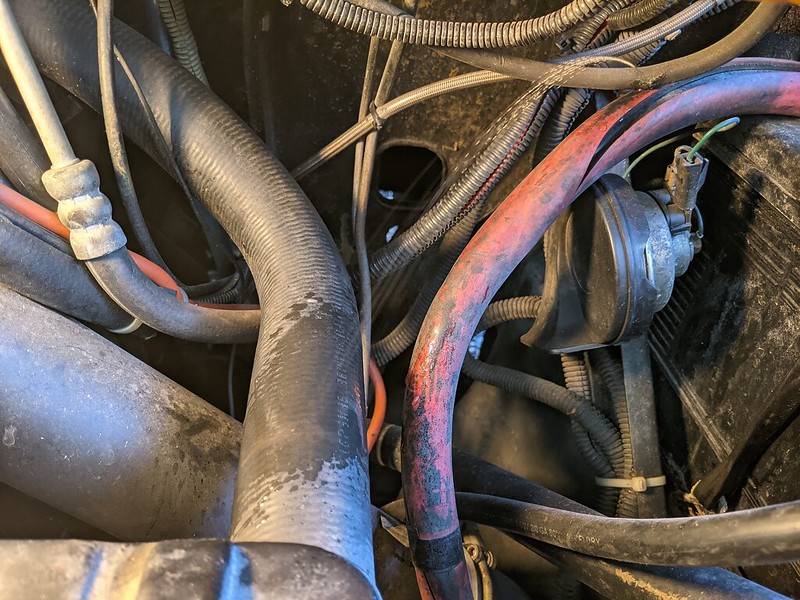

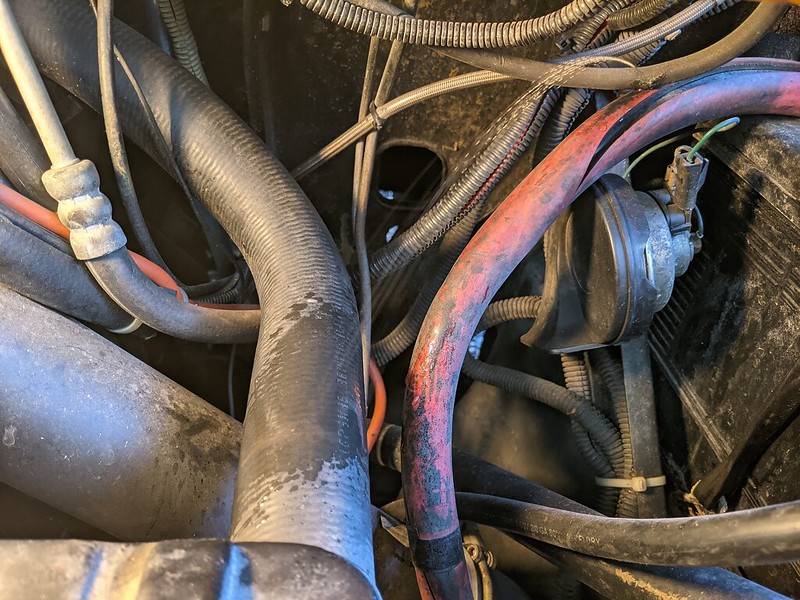

Good thing this rig isn't actually a boat, because it would be sinking. Getting coolant back in the system and leaks galore. So the cylinder head repair went "ok". I have confidence that we have stopped the crack from spreading. It is no longer dripping coolant out, but it is seeping just a tiny bit. I have some Blue Devil Block Seal I might through in there and that might fix that. If that doesn't work, maybe I'll get some K&W Block Seal as I hear that stuff is serious stuff, but it is quite the procedure. I've heard good things about sawdust from some shady used car dealership friends of mine. And I also have lots of extra JB Weld we can squirt into the coolant. Any suggestions, I'm all ears on this one.

Of course the radiator also decides to quit. Leaking between the plastic side tank and the aluminum core, down at the very bottom.

Those plastic tanks are garbage. Lets see how an all aluminum one does for us.

While wrestling the radiators around, a hose for the windshield washer fluid also sprung a leak. I was wondering why I was being squirted in the face while tightening the lower hose clamps on the radiator. But it's cold, in the teens, and I'm tired of dealing with all these wet fluids.

Of course the radiator also decides to quit. Leaking between the plastic side tank and the aluminum core, down at the very bottom.

Those plastic tanks are garbage. Lets see how an all aluminum one does for us.

While wrestling the radiators around, a hose for the windshield washer fluid also sprung a leak. I was wondering why I was being squirted in the face while tightening the lower hose clamps on the radiator. But it's cold, in the teens, and I'm tired of dealing with all these wet fluids.

PlethoraOfGuns

Well-known member

I'm hunkered down in the back of the van right now. It's 14 degrees outside, but the diesel heater is keeping the inside a nice 62 degrees! Turn it on, set the thermostat, and forget about it! Good temperatures to really test all this heating stuff. Glad we're insulated. Block seal will be a go. Got nothing left to lose. Question is, which product will work best on a seeping cast iron crack like this one?

Last edited:

PlethoraOfGuns

Well-known member

Oh criminy, it's getting cold. One thing that's as bad in the cold as molasses in January is LiFePo4 batteries. I'm afraid if I don't run the heat, the batteries are going to get too cold and then they will blow up.

Through some easy research, I find that I can get this temperature probe that communicates to the other Victron equipment, and now if the batteries get below 40 degree, the charging is shut off! Self adhesive to the top of the battery and fused right to the battery. Perfect, I'll be able to sleep at night when I don't run the heat.

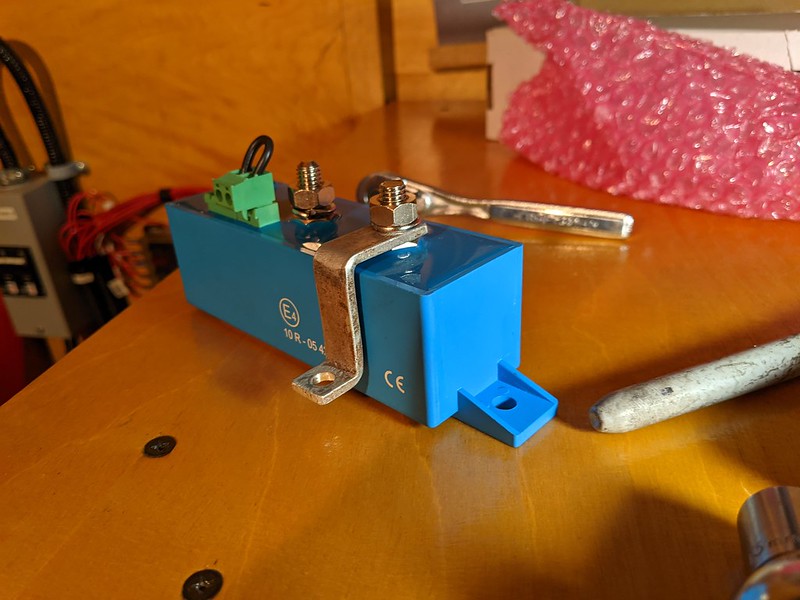

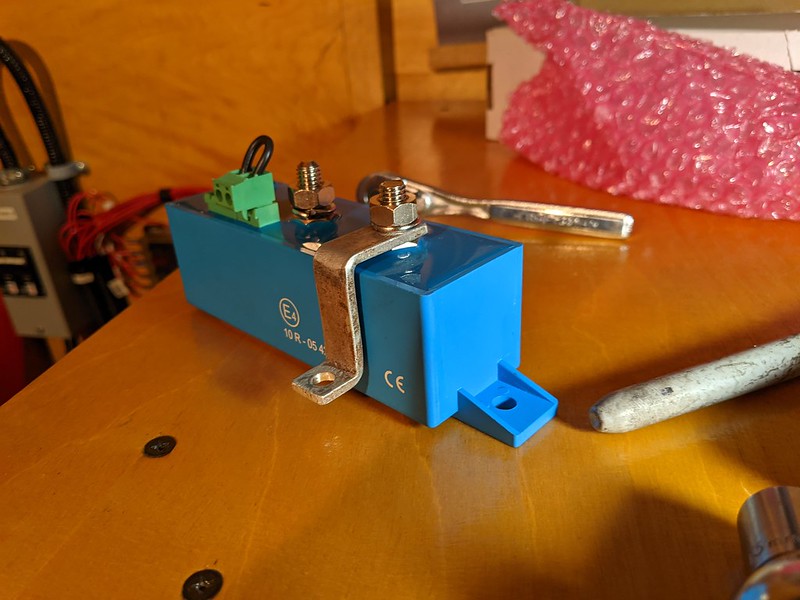

While I'm at it, got some low voltage protection too. This is a shut off relay so all the loads from the battery are disconnected if the battery gets down to 10%. Cut and bent my own busbar to attach to circuit breaker. Only thing this doesn't shut off is the inverter.

Easy as pie. With all the bluetooth stuff we can easily monitor everything from the phone. The Victron stuff is worth the extra cash I think. Very well built units and love how everything can be tied together.

Through some easy research, I find that I can get this temperature probe that communicates to the other Victron equipment, and now if the batteries get below 40 degree, the charging is shut off! Self adhesive to the top of the battery and fused right to the battery. Perfect, I'll be able to sleep at night when I don't run the heat.

While I'm at it, got some low voltage protection too. This is a shut off relay so all the loads from the battery are disconnected if the battery gets down to 10%. Cut and bent my own busbar to attach to circuit breaker. Only thing this doesn't shut off is the inverter.

Easy as pie. With all the bluetooth stuff we can easily monitor everything from the phone. The Victron stuff is worth the extra cash I think. Very well built units and love how everything can be tied together.

angelmander

Member

- Joined

- Jul 17, 2019

- Messages

- 19

- Reaction score

- 1

https://vanlivingforum.com/threads/finished-van-conversion-just-left-home-in-it.39033/Agreed. So many things can be fixed and be good as new. But cast iron is a crap shoot. we'll see what happens.

Oh no way! Step vans are the best! Do you have a build thread somewhere? I'm always looking to see what other creative things people do.

PlethoraOfGuns

Well-known member

Thanks for sharing your step van build! Looks great! I need more step van action!

Similar threads

- Replies

- 12

- Views

- 3K

- Replies

- 22

- Views

- 3K