One Awesome Inch

Well-known member

- Joined

- Nov 14, 2013

- Messages

- 1,170

- Reaction score

- 0

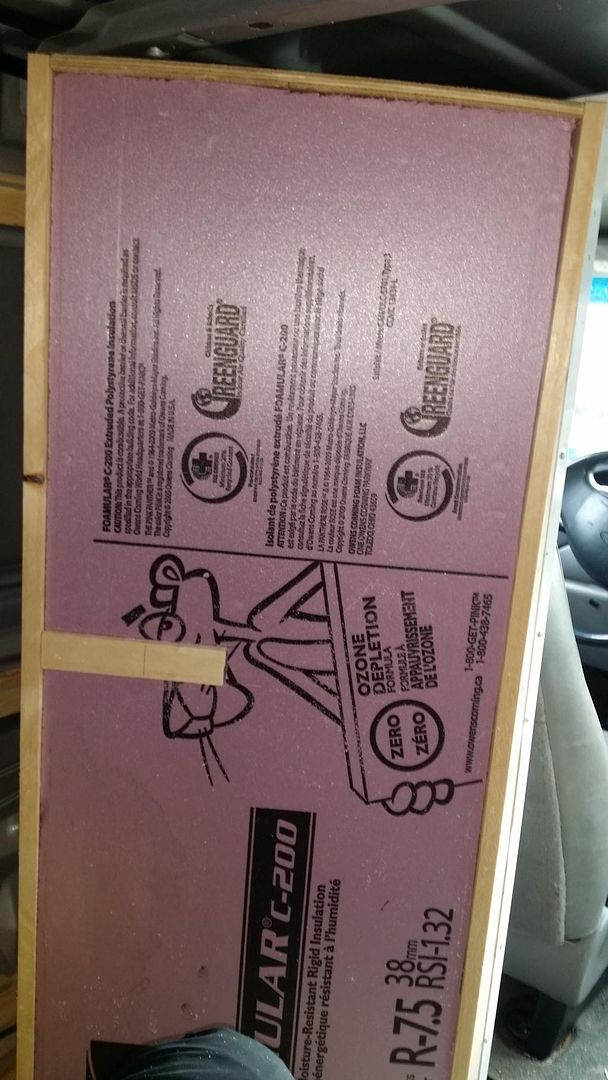

Duck, I very much appreciate your generosity. The only thing I really need at this point is half inch foamboard insulation. That will be costly, but necessary. Thankfully, I have all the tools I need. The guy who sold me the van told to just keep its contents because he didnt want to have to deal with it all. The biggest thing was a mitre saw which I just sold on CL. I am mainly using a cordless drill, cordless circular saw from Black and Decker. They seem to be serving me well. As to fasteners I haven't had to buy any yet as the van had a couple small buckets full of them when I bought it.

Thanks again for your generous offer.

Thanks again for your generous offer.