I don't know if they work on more than one type of van or if they offer more than one type of conversion. If this is the only model they offer, they can probably knock off at least 2 per day. They seem to have every move and every detail worked out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Korean company choreographs van conversions.

- Thread starter MGfromBC

- Start date

Help Support Van Living Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

eDJ_

Well-known member

As the Van Nomad movement and interest in home built RV's grows in the States this may give Ford, GM, and Chrysler some incentive to consider creating their own software programs to customize their Vans as well. Years ago I read Ralph Nader's book "Unsafe At Any Speed" and remember his discussion of "aftermarket" auto components which evolved to satisfy owners needs the factory hadn't considered or anticipated. It began with something called a "camber compensateor" which when installed would help to prevent the Corvair from flipping over in turns. These were also produced for other rear engine cars such as the VW Beetle. (I bought one for a VW I once owned and it made quite a difference) Nader's point is still relevant concerning the momentum of third party after market trends. These trends may follow the engineering shortcomings, needs for better safety, (seat belts were owner installed options before they became mandated and likewise the third brake light in the rear window was an aftermarket accessory before Elizabeth Dole mandated it be a requirement on all cars) the economy, and just innovations originating from the public. Think back to those custom vans from back in the late 60's to 70's setting an example for many of today's younger Nomads.

I would credit Volkswagen since the post WW2 era with their CamperVan for introducing the idea into the USA. There had been things like it produced here in the earlier half of the 20th century but due to world wars and the depression the idea had waned away. Until 1947.

I would credit Volkswagen since the post WW2 era with their CamperVan for introducing the idea into the USA. There had been things like it produced here in the earlier half of the 20th century but due to world wars and the depression the idea had waned away. Until 1947.

VW Campervan - The Evolution. 1947 marked the beginning of campervans. Dutch importer Ben Pon had the idea from observing motorised trolleys which were being used to transport parts around a VW factory in Wolfsburg.

I suspect the company that designed and commissioned these units is located in Australia. The labor cost is lower in Asian countries. So more profitable to have a vehicle sent direct to them from a factory and then put it onto the cargo ship for delivery at the port in the destination country.

The work crew is very well trained and practiced in efficient assembly. The workspace is well tooled up and arranged. The flow of materials is good. A class act operation that follows the principals of Kaizen manufacturing. It is always great to see it in real-time action.

The work crew is very well trained and practiced in efficient assembly. The workspace is well tooled up and arranged. The flow of materials is good. A class act operation that follows the principals of Kaizen manufacturing. It is always great to see it in real-time action.

Hint if you want to build a 3! CAD model of the inside of your van start by establishing a fixed point inside the van as your temporaty 0,0,0 location until you establish a preferred one . Everything is located related to a 0,0,0 X,Y, Z. A factory installed hole on the floor in the rear of a cargo van is a good temporary 0,0,0 to choose as you can set up some large, accurate squares and additionally use laser levels to get vertical and horizontal reference lines, If you wish, for convenience, the roof beams can be marked with measurements for a quick reference as can be the floor and the ribs on the wall. But do double check to make sure those marks are accurate related to 0,0,0 in your CAD model.

I recently watched a video of a couple who do conversions for a living. For most of the plywood walls and many other pieces, they had full size paper drawings that they gued to the plywood, cut out and stripped the paper. I don't know if these were their own or purchased.

That is definitely the low tech way to do a van build business but it certainly does work when you can’t afford to buy equipment or simply do not want to use “high tech” production methods.I recently watched a video of a couple who do conversions for a living. For most of the plywood walls and many other pieces, they had full size paper drawings that they gued to the plywood, cut out and stripped the paper. I don't know if these were their own or purchased.

If I myself if I did not want to get involved in CNC and wanted to do repeats of the same designs I would create durable router templates for majority of the pieces. I have done that as well as a lot of jig building for accurate positioning and repetition of parts fabrication.

I am an unusual woman, since childhood when I always had a passion for architecture and interest in “making and designing” things and always wanted to learn wood working. Later but still in childhood I was learning some commercial sewing methods of accurate parts replication from my mother. As a young adult l accepted a job opportunity to do some architectural drafting. As a young newly divorced mother I was offered a job to be an aircraft installation and fabrication mechanic at Boeing. After I left there I was doing some 3D CAD work for a couple of product designers who created automated machinery. Also helping them create physical prototypes. I did my first van conversion in a VW bus in early 1983. I learned to think in 3D and take accurate measurements 60 years ago! I attended the first PC computer fair in Seattle 1980 and bought my first PC in 1982 and learned my first 3D CAD program in 1988 while still doing hands on fabrication and installation work at Boeing where I eventually became a lead. And later took short term contact jobs as a lead at other companies who were doing sub contract work for Boening and needed to proof the jobs and organize their work flows for efficiency and train employees for the assembly and tools involved.

Me at work at Boeing where I was fabricating and installing parts on a full scale mockup for an extended 737. It was excellent experience as I got to learn to build jigs and work in lots of materials and got taught the precision woodshop methods I had always wanted to learn along with learning how to do some fiberglass work and using tools like a press brake.

Of course I have also done considerable house remodeling and some furniture building over the years. Plus had My own dream workshop. But eventually spinal injuries made standing at a work bench and a tablesaw etc too painful to be productive. So my last big project was doing a full on renovation of my 53 year old travel trailer. Now I just teach and advise and encourage women to learn to use tools. Plus I still design and fabricate 3D paper craft miniature cardstock village kits that I sell online. “Going tiny” and downsizing worked for me and it keeps my brain thinking and visualizing in 3D and solving problems of construction.

Last edited:

I've been following 2 women on You Tube who go by the name Vanwives. I'm not particularly interested in anybody's van travels, but 3 years ago they bought a run down cabin in rural Nova Scotia and have converted it into an oasis. Their tool collection and accumulated skills have been a fun journey to watch. Recently they bought a piece of land in Mexico to build on.Now I just teach and advise and encourage women to learn to use tools.

https://www.youtube.com/@Vanwives

eDJ_

Well-known member

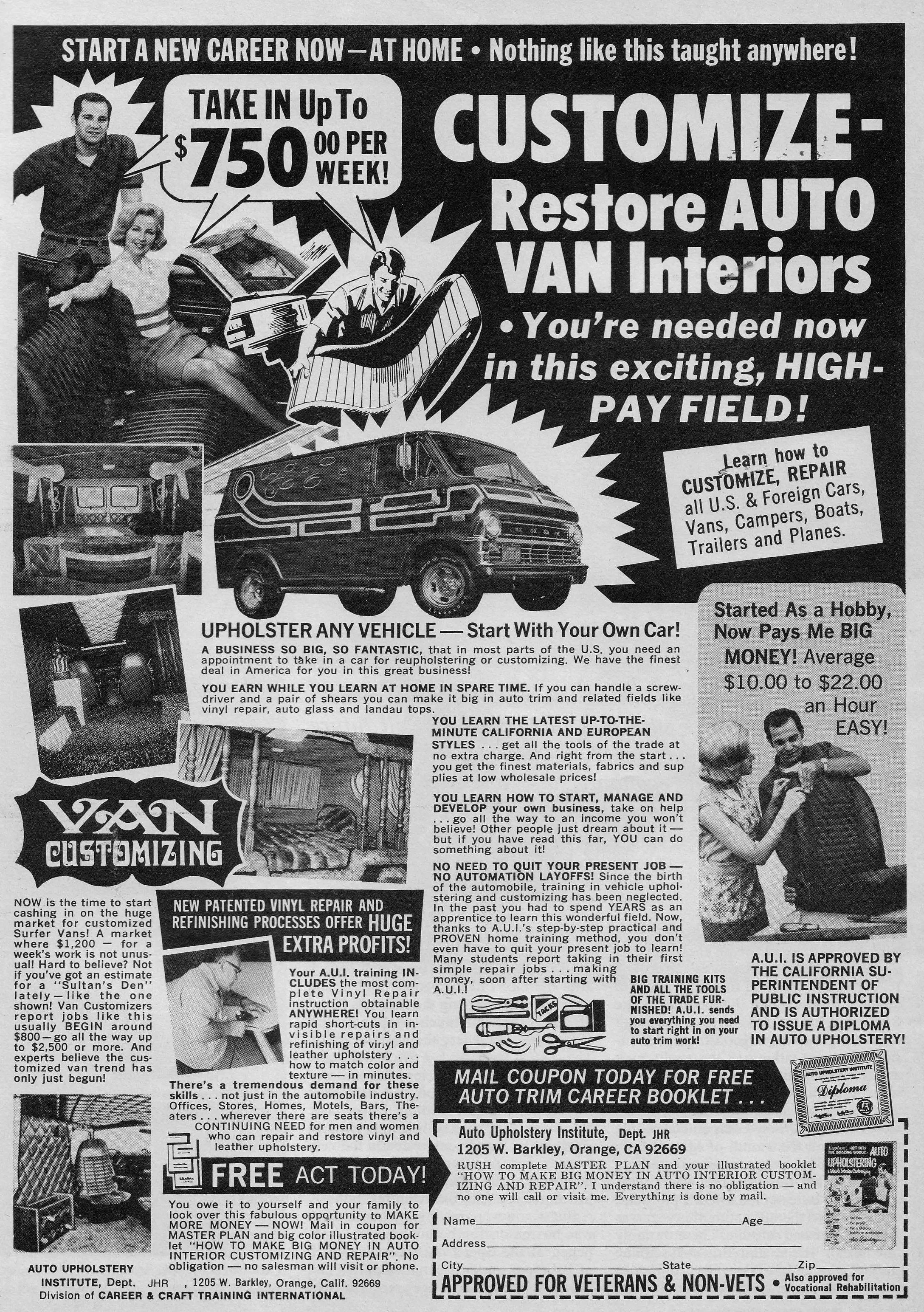

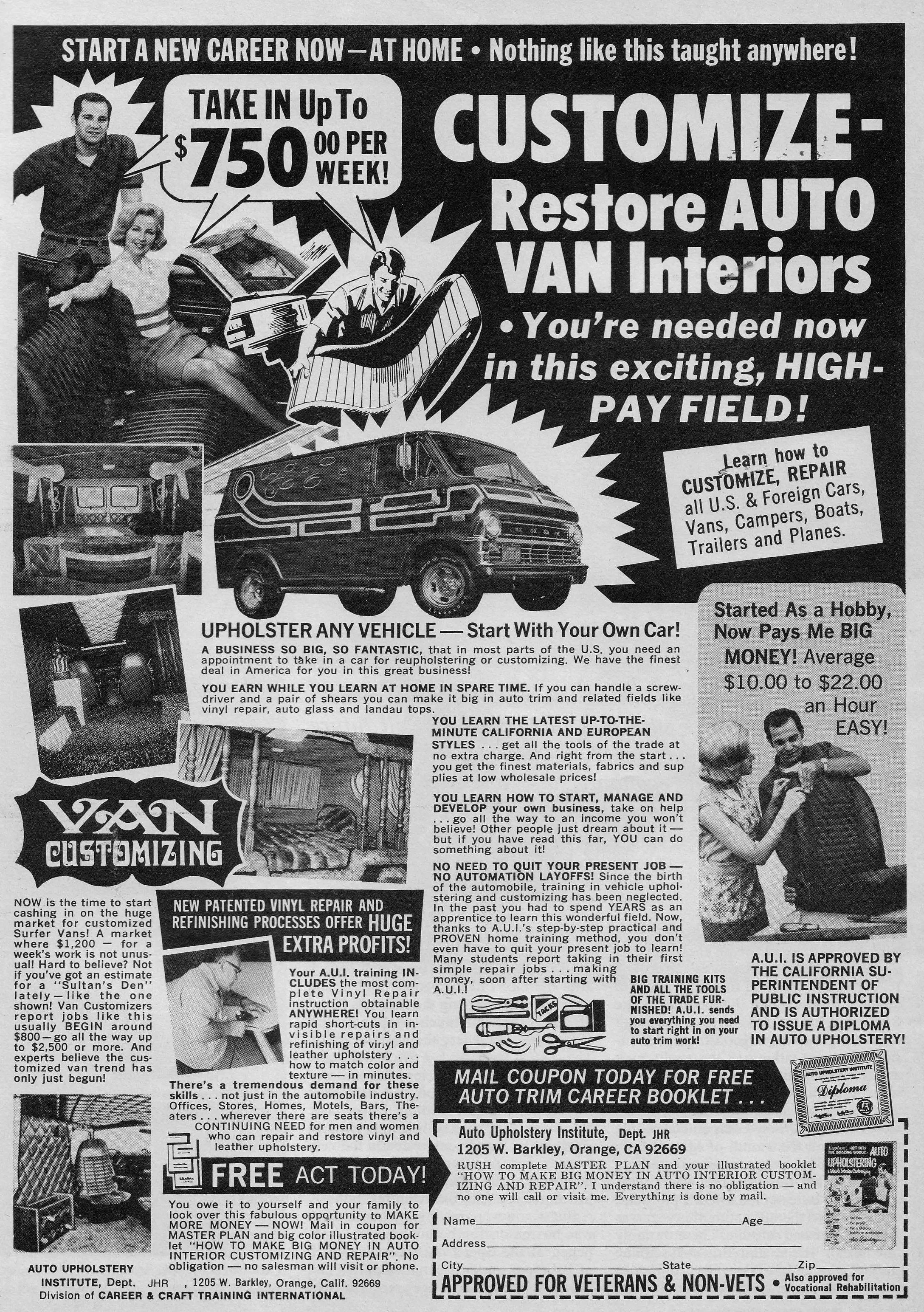

Back in the late 60's and into the 70's when custom vans began to become the thing so many people were getting into, magazines began to show up on the news stands. Many of them had advertisements from companies offering paper patterns one could use to cut out panels from plywood (for the flooring) or wood grained paneling for the walls and ceiling. They were something like thirty dollars a set and offered them for the popular makes and lengths of vans.

Those patterns are still available today but rather costly. I would suggest taking care of them so they could be reused or sold on the aftermarket.

Timber is a company that offers paper patterns for making the paneling for your build.

TimberVanKits com

In the custom van craze there was some interest in short term camping but there were no computers, cell phones, or internet back then, so the van was more for social gathering, surfing at the beach, going to rock concerts etc. Of course some built their vans for hunting, fishing, and camping trips. A smaller sector built them to use as a home away from home and many of them worked construction or short term assignments too far from home to commute every day.

When insulating and paneling a van, one should consider moisture barriers as heat inside and cold on the outside may lead to condensation. This can lead to mold or rusting. If you are starting with an older van it may not be such a worry as you will likely only be keeping it for a few years before looking for a newer rig with lower mileage.

Business customizing vans in the 1970's ad's

A blast from the past

Days of the Shaggin Wagon

Those patterns are still available today but rather costly. I would suggest taking care of them so they could be reused or sold on the aftermarket.

Timber is a company that offers paper patterns for making the paneling for your build.

TimberVanKits com

In the custom van craze there was some interest in short term camping but there were no computers, cell phones, or internet back then, so the van was more for social gathering, surfing at the beach, going to rock concerts etc. Of course some built their vans for hunting, fishing, and camping trips. A smaller sector built them to use as a home away from home and many of them worked construction or short term assignments too far from home to commute every day.

When insulating and paneling a van, one should consider moisture barriers as heat inside and cold on the outside may lead to condensation. This can lead to mold or rusting. If you are starting with an older van it may not be such a worry as you will likely only be keeping it for a few years before looking for a newer rig with lower mileage.

Business customizing vans in the 1970's ad's

A blast from the past

Days of the Shaggin Wagon

Last edited:

Technology has evolved. There is software that will allow you to take 3D scans of the interior of your van yourself. But it does take some patience and skill to stitch together the multiple scans needed for large objects and then clear up the extraneous data in the scans. You will also need to learn 3CAD software and for things like wall panels how to flatten a curved object such as a wall panel into an accurate flat panel and then make a printable pattern or at least a dimensioned drawing. Fortunately there are a lot of YouTube tutorials as well as online user groups for the various scanner and CAD programs that will teach you what you need to know. Of course this we’ll add lots of extra months of time to your build project. The fastest way for designing your own interior is to get some cardboard and masking tape and go into the van and make templates the old fashioned way.

I designed the majority of my custom cabinets for the full renovation of my 53 year old molded fiberglass in 3D CAD and created measured drawings from that model in 2D CAD. There were only a few minor pieces where it was easier to make a cardboard template where there is an radius where the sloped wall transitions to the roof which itself has a slight slope down to the walls from the fore and aft centerline. It in a 53 year old fiberglass trailer the floor and walls were no longer truly flat. So what worked best was to deign in CAD, fabricate the face frames of cabinets fix them in place squared up to a centerline on the floor and take individual measurements for the framing members that went over to attach the face frame to the exterior walls. With a door that was narrower than the cabinet depth and a floor that was no longer flat width wise the cabinets could not have gone in preassembled. A metal van with wide doors would have been an easier build for custom cabinets as well as the roof panels. But despite the challenges of a wonky space my aluminum angle framed cabinets came out looking very nice. My trailer has a rear entry door so there is another set of cabinets on the other side plus across the front end where my bed is. I have approximately 14 linear feet of countertop space and lots of cabinet storage space. The cabinets in the photo have a slide out fridge and portable toilet incorporated into them and a shallow sliding door pantry is up top. The desktop with the vinyl cutter on it is removable should I ever want to put in a double wide bed platform. In no way does the interior resemble the 1971 original. That metal post is a roof support, there is a popup roof over the rear half of the trailer.

I designed the majority of my custom cabinets for the full renovation of my 53 year old molded fiberglass in 3D CAD and created measured drawings from that model in 2D CAD. There were only a few minor pieces where it was easier to make a cardboard template where there is an radius where the sloped wall transitions to the roof which itself has a slight slope down to the walls from the fore and aft centerline. It in a 53 year old fiberglass trailer the floor and walls were no longer truly flat. So what worked best was to deign in CAD, fabricate the face frames of cabinets fix them in place squared up to a centerline on the floor and take individual measurements for the framing members that went over to attach the face frame to the exterior walls. With a door that was narrower than the cabinet depth and a floor that was no longer flat width wise the cabinets could not have gone in preassembled. A metal van with wide doors would have been an easier build for custom cabinets as well as the roof panels. But despite the challenges of a wonky space my aluminum angle framed cabinets came out looking very nice. My trailer has a rear entry door so there is another set of cabinets on the other side plus across the front end where my bed is. I have approximately 14 linear feet of countertop space and lots of cabinet storage space. The cabinets in the photo have a slide out fridge and portable toilet incorporated into them and a shallow sliding door pantry is up top. The desktop with the vinyl cutter on it is removable should I ever want to put in a double wide bed platform. In no way does the interior resemble the 1971 original. That metal post is a roof support, there is a popup roof over the rear half of the trailer.

Last edited:

Happy Camper

Well-known member

- Joined

- Jan 8, 2015

- Messages

- 2,617

- Reaction score

- 1,990

Similar threads

- Replies

- 82

- Views

- 4K

- Replies

- 3

- Views

- 1K

- Replies

- 63

- Views

- 6K

- Replies

- 8

- Views

- 1K

Latest posts

-

-

New to the forum, and may become a van lifer soon. Good to be here!

- Latest: smokeshadow

-

-

-

-