--------------------------------------------------------------------------------------

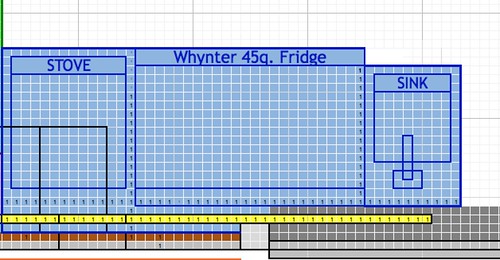

LUNCHBOX LOCKER INSTALL

----------------------------------------------------------------------------------------

My van had an open differential. This means that when traction is limited, and one of the rear wheels begin to slip, all the power ends up going to that wheel that is slipping, and none to the other (basically the opposite of what you would want). This was very evident when driving in the rain. If I tried to accelerate going uphill on a wet road, I’d have to only use a very small amount of throttle or one of the rear wheels would just start spinning. That was compounded a bit by the fact that the tires didn’t have a lot of tread left, and the van was empty.

I plan to spend a lot of time camping off of forest service roads and in various types of terrains (rocks/gravel, dirt, grass, sand, etc.). If this is what happens driving the car on a ROAD, it wasn’t going to cut it on the other surfaces.

I was starting to think about looking for a Limited slip rear end to replace this with, or one to take parts out of to install inside mine (if that is even possible..). A poster on another forum suggested that I consider

Lunchbox Lockers. I read about them and liked how they sounded. I bought one for my rear end (a Chrysler 9.25”). I bought a Power Trax Lock Right.

As I was researching rear end internals and the locker install, I was initially really worried about whether I would have to set things like gear backlash, bearing preload, etc. Those are much more complicated than I’m accustomed to doing. But with this locker, you don’t have to do anything to those parts. Installation required only removing the existing Pinion shaft and spider gears, and replacing them with other parts.

The locker installation was what felt like one of two most challenging conversion steps remaining (that and the electrical system install). This was also the last major change I needed to make to get the van ready for a trip out to see my family in August. They live out near the rocky mountains, and when I was last visiting them and discussing the van, I told them I’d bring it out in August to go with them on a trout fishing trip up in the mountains.

I spent about 2 full days researching locker specifications and design, and figuring out how to install it. (The manufacturer’s instructions are difficult to interpret because they are generic and are written to apply to all of their lockers, so there is a lot of “If your axles, have C-Clips, skip to section 2, if not …. blah blah blah..)

So anyways, I read the instructions a bunch of times and watched a bunch of videos on Youtube, and I re-wrote the instructions in entirety - in a checklist style so I could mark each step complete as I progressed with the installation.

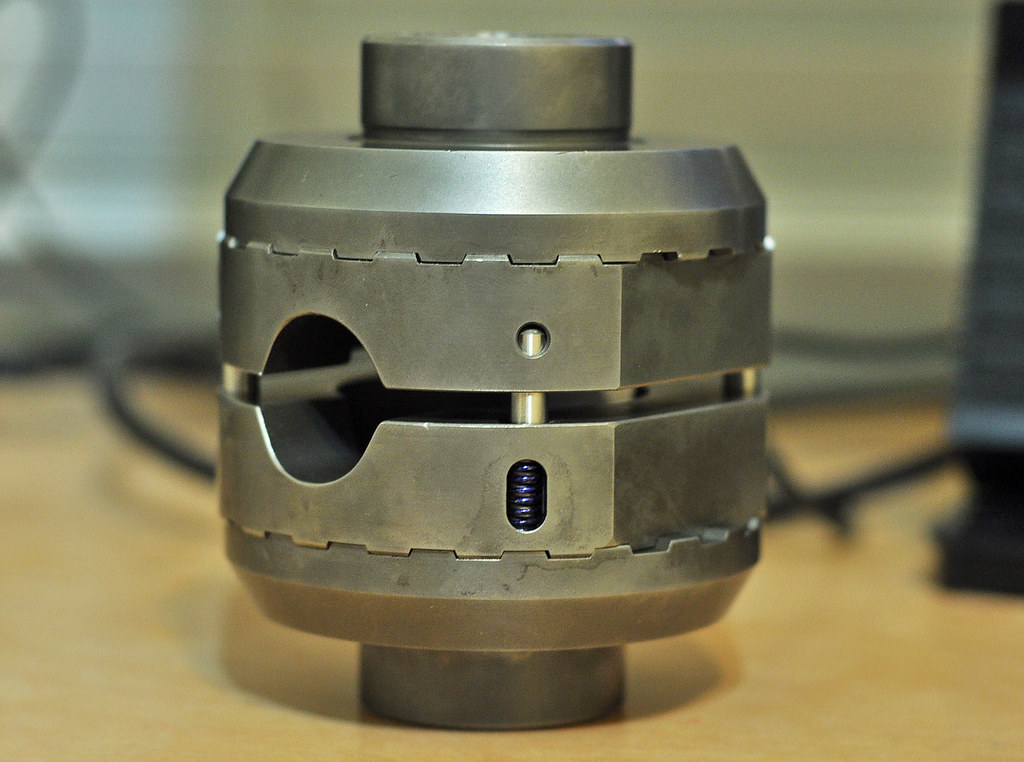

Here are the locker parts:

(this is everything except the Pinion shaft, which goes through the hole you see in the middle)

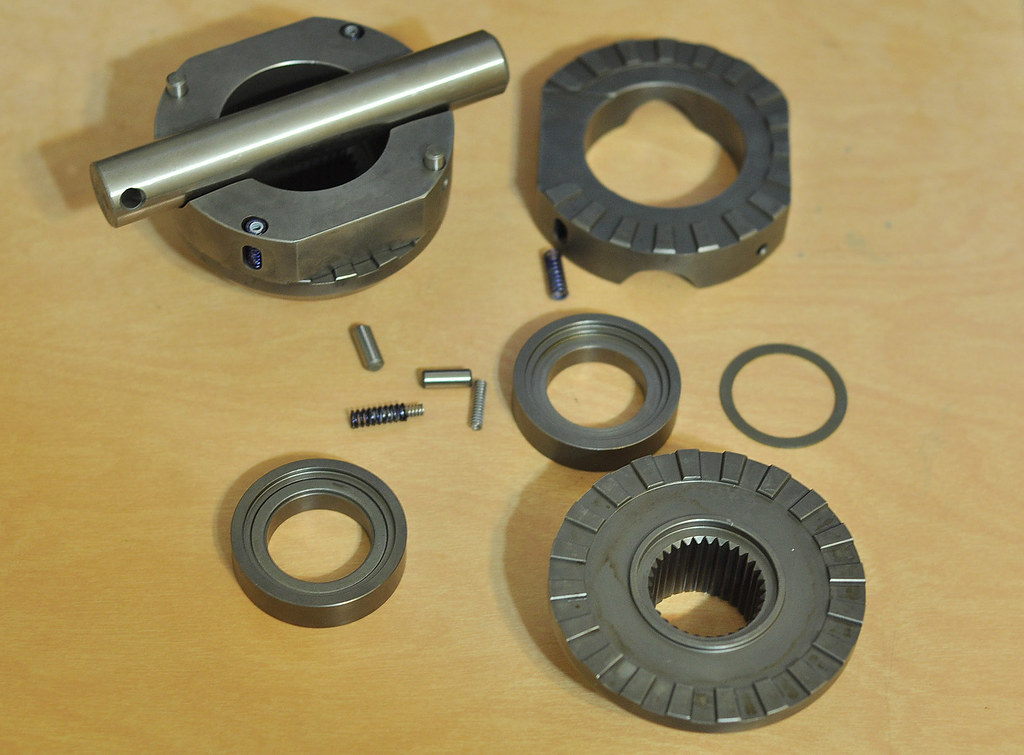

Here are all the pieces:

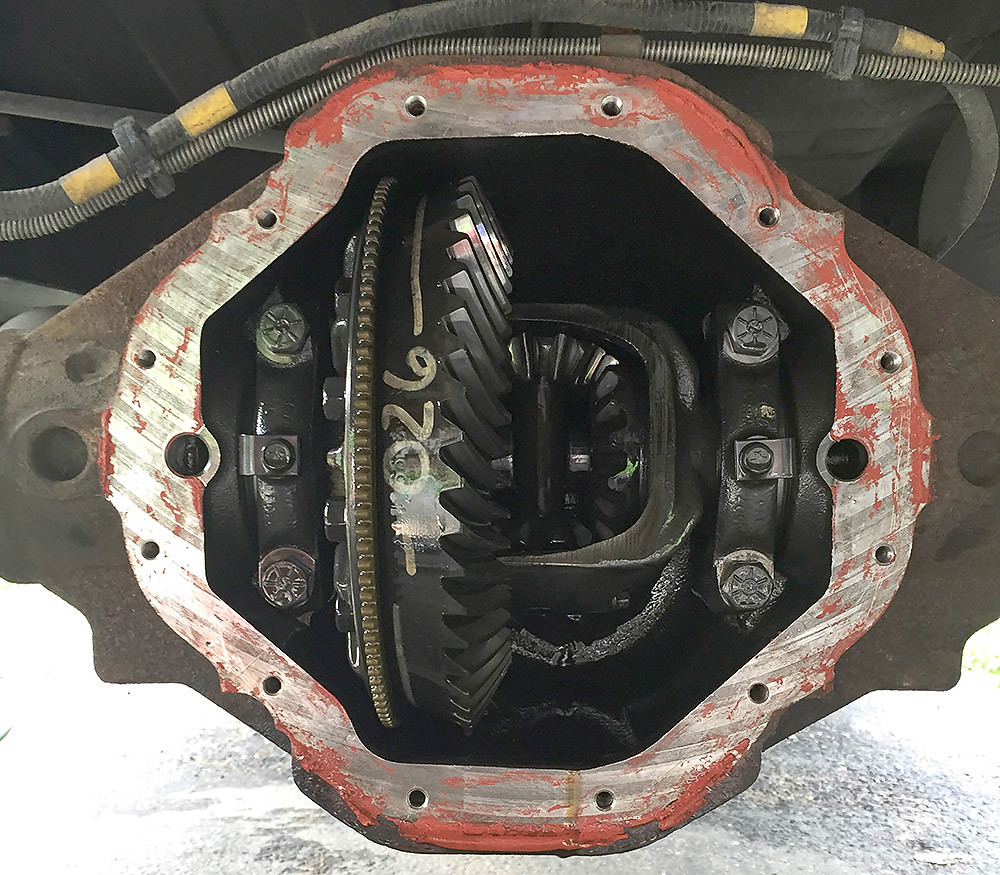

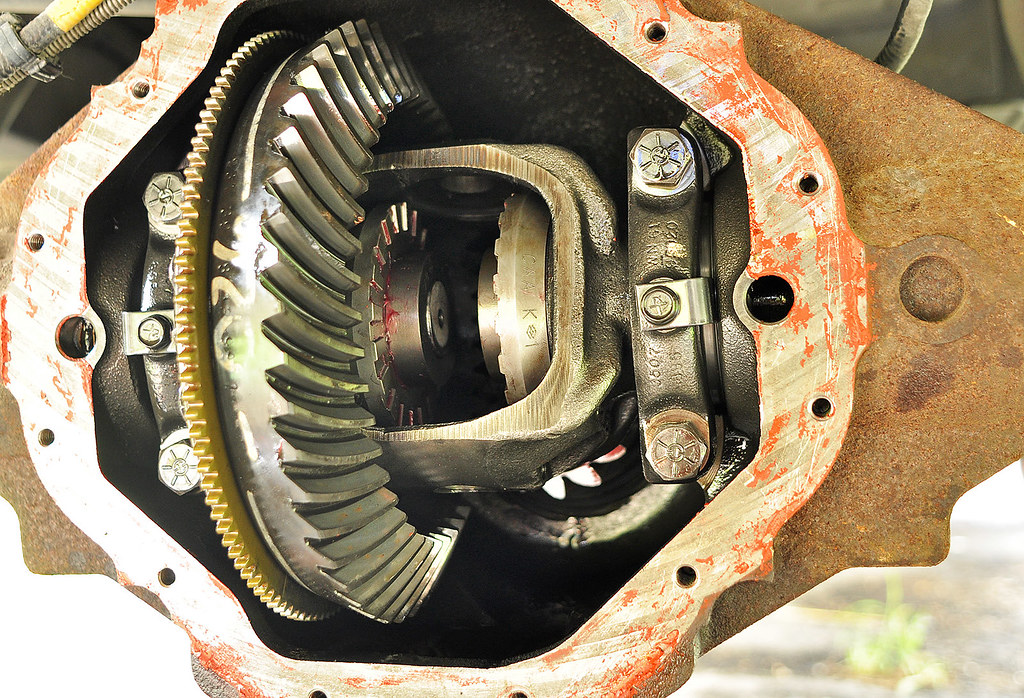

Here are the stock differential internals:

Here are the spider gears and side gears that I removed:

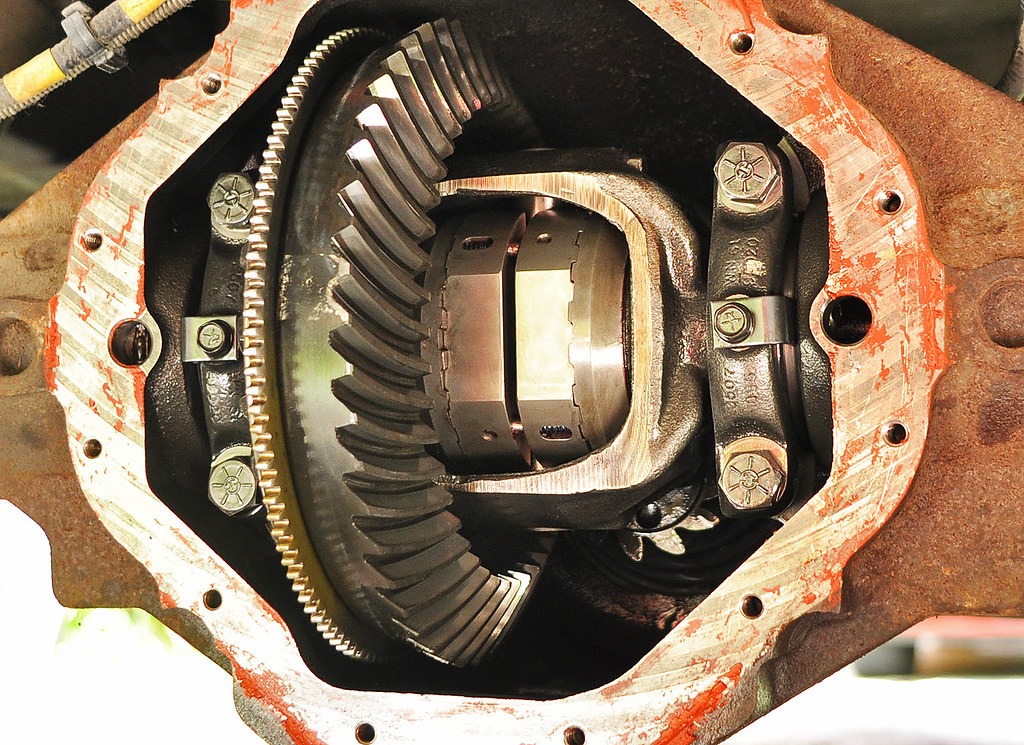

Here are the outer pieces of the locker installed (the ones that mate with the ends of the axles)

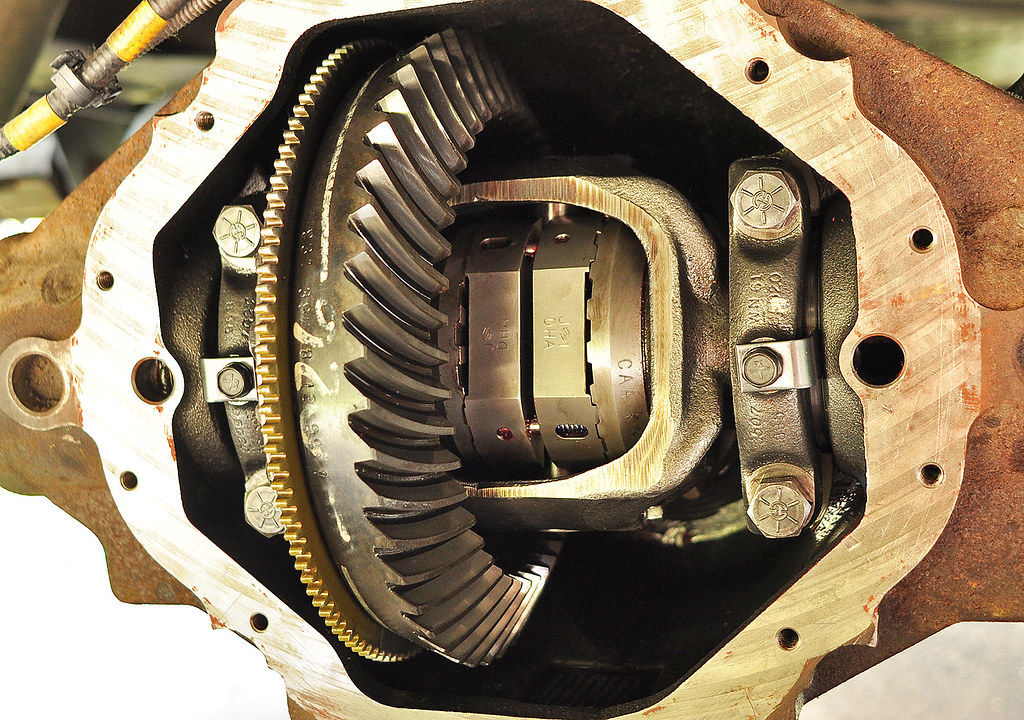

And here it is entirely installed. The hard part is getting in the last C-clip. You have to put the last C-clip in while all the pieces visible here are in place. You move one of the inner pieces over to the other side to open up some space between the mating teeth of the locker, and slip the C-clip in-between those and into the end of the shaft. It’s hard to get it in there and even harder to tell whether you really have it in place.

This picture has the locker rotated to show the other side. You can see that the inner/driver pieces have no teeth on part of them. This is so you can fit the C-clip in.

I reinstalled the cover (and made a new gasket), refilled it with gear oil, and tested it out. Everything went great with the testing except that when I was initially going back and forth in drive and reverse, I ran the van into the retaining wall that is at the top of my driveway (the wall turns and my driveway extends up further. I hit the corner because the van wasn't aligned well enough with the part of the driveway that extends further up). It bent up the rear bumper. The back door still opens all the way. I may try to get it bent back to the normal shape.

Anyways, it drives well. The clicking of the teeth while turning is audible, but at most times, just barely. It won’t bother me at all. The inner rear tire slips some if I apply throttle enough while turning. This will make the rear tires wear faster. I don’t know how much. Overall drivability is changed very little. I’m happy with it - and happy that the installation went well!

Time to charge onward!! (With two wheels :-D )