Michael T.

Member

- Joined

- Jun 6, 2017

- Messages

- 24

- Reaction score

- 0

So I bought a big 12 volt lithium battery(300 ah). I bought 6, 160 watt 12 volt solar panels, and a morningstar TS-60 PWM controller.

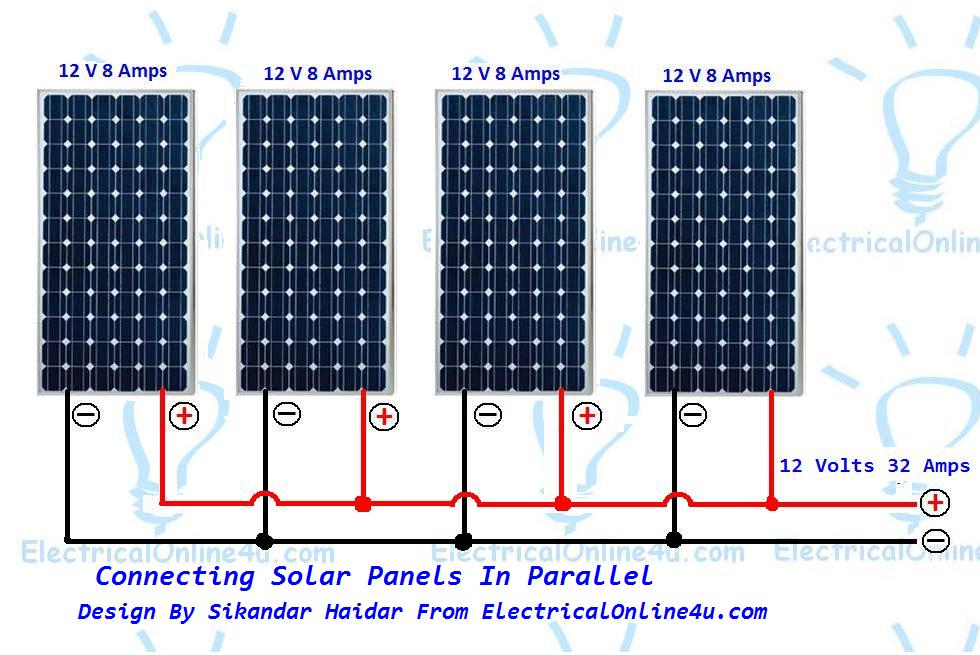

I want to wire the panels in parallel, but I do not want to bother with all the weird Y-branch connector nonsense and have a hoard of wires on my roof... I am considering taking two 10 gauge MC4 extension wires and running them along the roof of my van all the way to the front most panel in the array, then splicing into the wires at 5 places on the positive, and 5 places on the negative and connecting all my panels in a parallel circuit matching this configuration...but with bigger watt rating a bigger inverter and bigger battery.

Am I just young and dumb? Will I catch fire? please help me, I have no idea what I am doing.

I want to wire the panels in parallel, but I do not want to bother with all the weird Y-branch connector nonsense and have a hoard of wires on my roof... I am considering taking two 10 gauge MC4 extension wires and running them along the roof of my van all the way to the front most panel in the array, then splicing into the wires at 5 places on the positive, and 5 places on the negative and connecting all my panels in a parallel circuit matching this configuration...but with bigger watt rating a bigger inverter and bigger battery.

Am I just young and dumb? Will I catch fire? please help me, I have no idea what I am doing.