loess

Well-known member

- Joined

- Sep 25, 2012

- Messages

- 60

- Reaction score

- 0

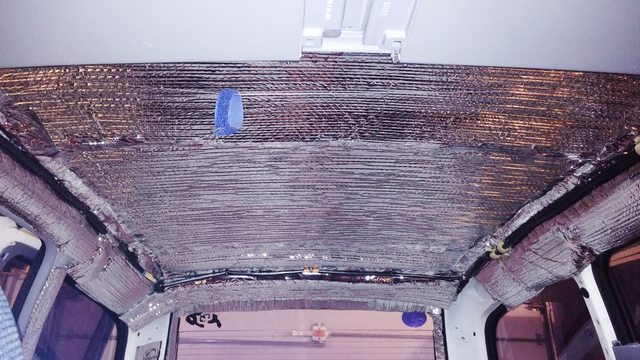

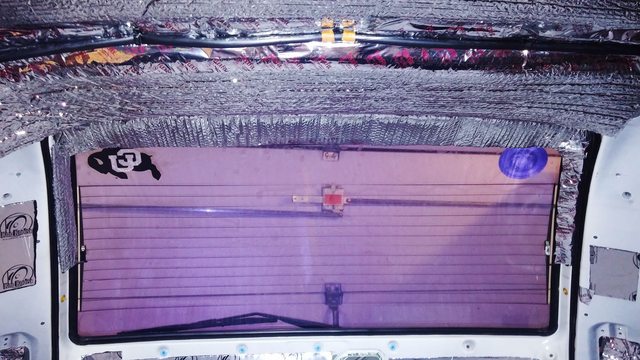

A few years ago, I decided that I was done dumping time and money into my little Volkswagen Rabbit pickup truck, and I knew I wanted something bigger that I could potentially travel in for longer periods. Somehow I got turned on to the Toyota Previa with its quirky spaceship egg shape, its reputation for handling pretty darn well in adverse road conditions, its spaciousness relative to other minivans, and its reputation for all-around mechanical reliability. So I set out to find me a good one. I hunted around for a while and as part of my search I posted a "wanted" ad on my local Craigslist, which lead to meeting my now good friend who is more or less a certified Previa-holic. Ended up traveling to Colorado with him where I found my dream van. I bought it from an older couple who had owned it for most of its life and they took very good care of it. When I was heading over to their house to meet them and look at the vehicle, there was a giant rainbow that was arc'd over their neighborhood. I knew right then that this was gonna be the one! So even though it's a plain white minivan, she is really the Rainbow Previa. I have traveled extensively with her over the past two summers and have spent a lot of time planning and preparing to transform the cargo area into a cozy little home for longer periods of traveling. Now that I have stripped it down to bare metal, it is time to get into the thick of the conversion process. Lots to do but have a nice chunk of free time between now and the new year, so I'm shooting to have the basics finished by January when I will head west for warmer and sunnier places!