I put in a lot of hours yesterday finishing the disassembly of truck interior...really was far more work than I anticipated.

Now and then in construction you do a job so well (or overdone) that the joke becomes "I pity the poor s.o.b. who has to demo this in the future...". I was sharing my similar thoughts about the upfitter who built out the box this week, and ended up getting a friend to come help for a bit...there was one particular steel drawer unit that was rather unmanageable alone. It only took about an hour before he was cussing the upfitter too... you had to have in reach at all times: square drive bits #1, #2, #3, phillips #2, #3, torx #2, and 3 different socket drivers. Anyway...

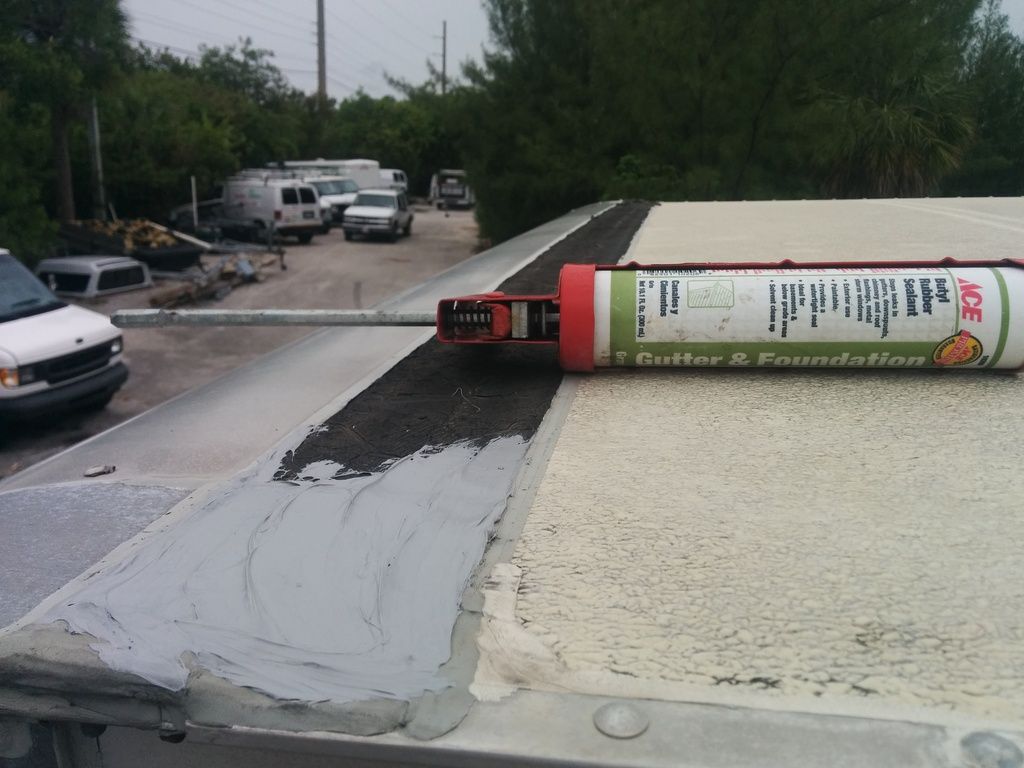

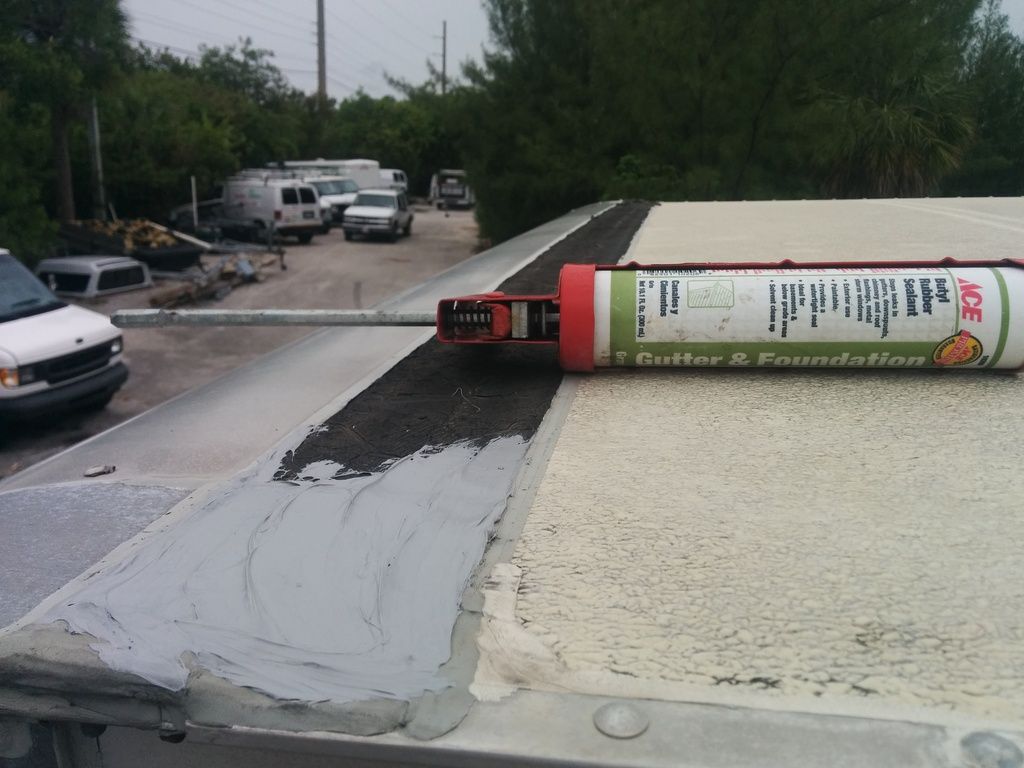

Fixed a couple roof leaks too:

Now and then in construction you do a job so well (or overdone) that the joke becomes "I pity the poor s.o.b. who has to demo this in the future...". I was sharing my similar thoughts about the upfitter who built out the box this week, and ended up getting a friend to come help for a bit...there was one particular steel drawer unit that was rather unmanageable alone. It only took about an hour before he was cussing the upfitter too... you had to have in reach at all times: square drive bits #1, #2, #3, phillips #2, #3, torx #2, and 3 different socket drivers. Anyway...

Fixed a couple roof leaks too: