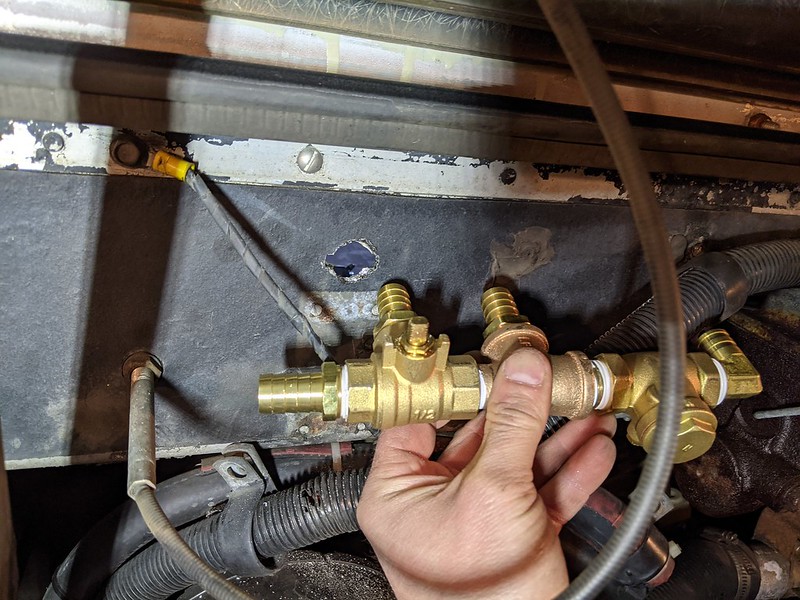

Ice is powerful force. Even the metal ones would crack under the right conditions. Yes, they are very expensive. For the same price I could have either gotten all the Sharkbite stuff like I done did, or get the crimper and crimp fittings. My brother mentioned the flexibility of changing things around on the road or repairs/maintenance, the Sharkbites would be a benefit since they can easily be removed and reused. I already had a leak and had to remove like 6 or 7 fittings to fix it, so that was nice. Most of the piping is in one very small area, and getting a crimper in there might have been a challenge. If they hold up, the shark bites were the right move I think.