highdesertranger said:

igbt that's very cool. how do you flip the cab to get to the engine. highdesertranger

The camper can raise up high enough on the removable jackstands to allow the cab to tilt (it isn't that often you actually have to tilt the cab actually).

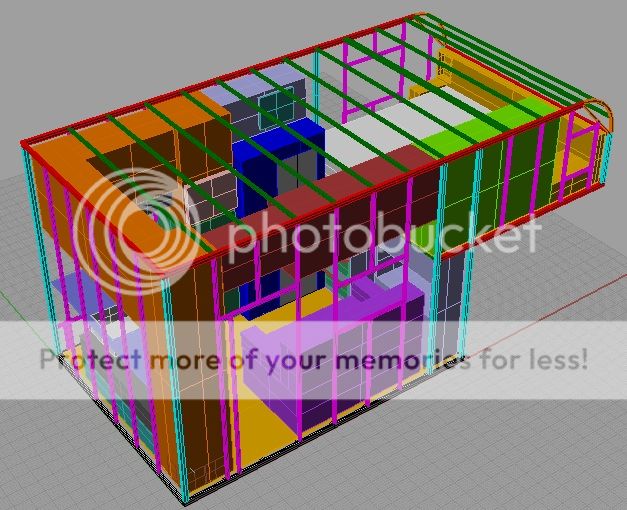

The garage pod we are constructing that will go where the motorcycles are now is the same width, 10 feet long, and 7.5 feet high with a roof rack for kayaks and such. It will also have the same sockets for our plug in jackstands so both the garage pod and camper can be placed on the ground if desired and the 20 foot flatbed can be used for hauling stuff. The garage pod will have a rear 8 foot by 2 foot workbench welded to the frame, tie downs for motorcycles, and overhead cabinets on each side for gear/tool storage. I plan to have a small mill/lathe mounted to the workbench as I can't live without a cnc milling machine. I probably will keep the Miller 211 welder in there also as it has been so handy MIG welding the tubular steel frame on both pods.

One might initially think a steel frame would be too heavy, but I used thin wall steel where I could and used angle sections to reinforce. The frame for the camper came out at about 700 pounds and the garage is about 500 pounds including the ramp door. The dry weight of the camper is under 3600 pounds and the dry weight of the garage should be under 1500 pounds. The truck base weight including flatbed is about 8500 pounds and it has a GVWR of 19,500 pounds. Essentially this means we can have around 5000 pounds of gear, water, food if needed.

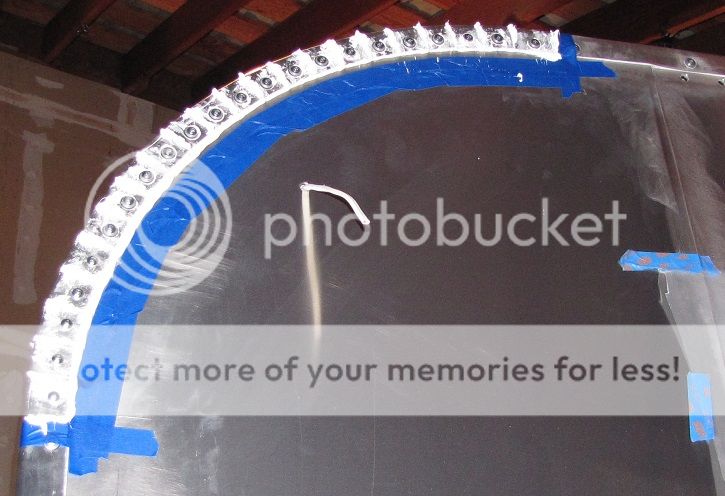

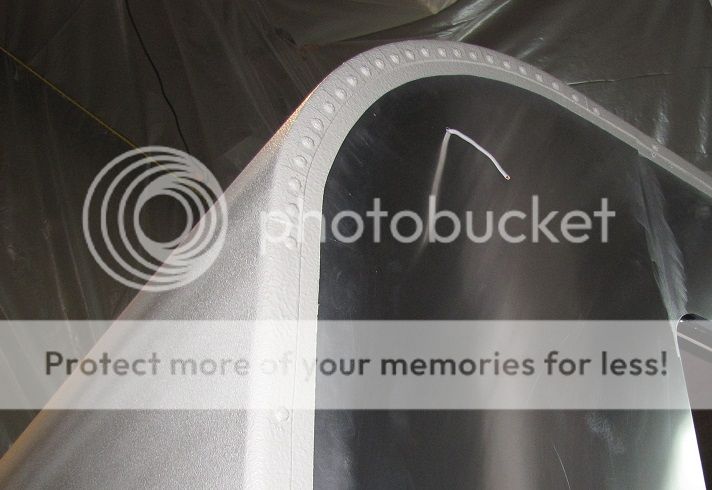

The roof is one piece 0.040" aluminum over 1/2" marine ply, tyvek barrier, then the steel frame. It is a continuous roll that has no seams or holes anywhere. It is folded down around the sides, front and rear, then sikaflexed and screwed on the sides. We then covered the whole roof with truck bed liner. In about 20 years we should inspect the roof for leaks

For the interior, we are using maple, walnut, and appleply (an amazingly well made maple faced plywood). The kitchen counter is 1-1/2" thick solid walnut butcher block. We have a 4kW Magnum inverter/charger that can also do generator sharing with our Honda EU2000i to give 6kW (probably never needed). On the roof we have 1100 watts of solar arranged as 2s2p feeding ~70v at 16 amps into a Midnite Classic 150 MPPT charger, which in turn will charge the Lifeline AGM batteries at 24V and ~40 to 50 amps. The 9.1cu-ft refrigerator is a Nova Kool compressor model with Danfoss brushless compressor. It uses about 500 watt-hr per day.

For insulation we went with 2 inches of polyisocyanurate fire resistant foam in the floor, walls and ceiling. Because of the care in the steel frame design, there is at least 1 inch of insulation between any steel frame member and the inside of the camper for thermal isolation, and there is 2 inches between the 0.063" aluminum siding and the inside. The insulation is rated at R13 per 2". The windows are all double pane. There is a 6 gallon water heater and a 19,000 BTU furnace, along with a 37 gallon fresh water tank and 37 gallon gray water tank, both contained under the kitchen counter and heated. The toilet is a Thetford cassette model with a removable 6 gallon cassette (will carry an extra) that can be dumped in a pit toilet or regular septic system.

I have a ton of pics but I don't want to eat up the bandwidth of those rv'ers who may be on 3G.