So this whole problem could have been sorted out with a small flashlight velcroed to the dash?

I assume you meant 120Vac LEDs? As 12v leds of course require no inverter.

I did get a response from my electronics guru contact regarding this.

The odds are that the logic in the inverter is intended to be powered up first before allowing current to flow into a load. As you figure, the power switch would take care of any necessary sequencing. On a lot of these type devices, they're not totally off, but in a low current quiescent state while the power switch is off. The switch is more of a standby switch in those cases.

The output devices are probably rated for surviving the full rated load (temporarily...) but motors do generate large spikes during startup and shutdown.

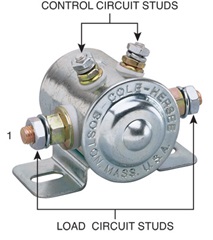

Depending on the capacity of the inverter, the solenoid might have to be a pretty hefty one to keep resistance in the circuit low. I generally detect interruption in a high current circuit.

What do you think the odds are that he just wants to power up some sort of AC powered power supply to operate/charge a DC powered device, and he just doesn't know about buck inverters and PWM.

I'm with you on rerouting the power switch wires. It may be possible to parallel the existing wires right at the switch, without even removing the switch. Depends on whether the wires are soldered or quick connects. A great many people have zero to negative talent when it comes to compact high reliability wiring though, so he may be copping out by using the extra lines solenoid, as there are diagrams for how to wire them up all over the net.

So basically there is potential risk to the inverter by having a solenoid opening or closing the circuit with the inverter turned on wqith appliances plugged into it that are also set to on, much better to turn the inverter on and off with its own switch.

However small loads of 120Vac LED lights might not be much of a load or cumulatively damaging to any measurable degree, but I would not be opening or closing the DC circuit to the inverter on any higher wattage appliance or something with a motor/ start up surge.

By the way, your 120Vac LEDS, well the inverter inefficiency likely eats up more battery power than the LEDS themselves do. I assume the 120VAc LEDs also have a power transformer on it to knock power down to XX volts DC, Knock off another 20% efficiency for this.

This double power inversion is a big waste of power. converting DC to AC, then AC back to DC, all on an appliance which can be run on DC directly.

Inverters are not the solution. They are a necessary evil, best bypassed whenever possible. LED lighting screams bypass the inverter.

If the LED lights you are powering on the inverter use a wall wart or inline power brick, what does the DC output voltage say on them?

Here is a simple voltage boost converter , that can step up voltage from 12.x to 32vDC, and do so much more efficiently that using an inverter to sterp up 12.xvDC to 115Vac then back down to 32vDC.

https://www.amazon.com/Geeetech-Converter-10-32V-Voltage-Charger/dp/B00NK4LOBC

https://www.amazon.com/dp/B06XTBR15W?psc=1

I have the first link, bought for $2.50 slow boat from china, but the only thing I have used it for is to turn worn out 12v muffin fans into hovercraft at about 26 volts.

A DC voltage reducing device is called a buck converter.