Cory350

Active member

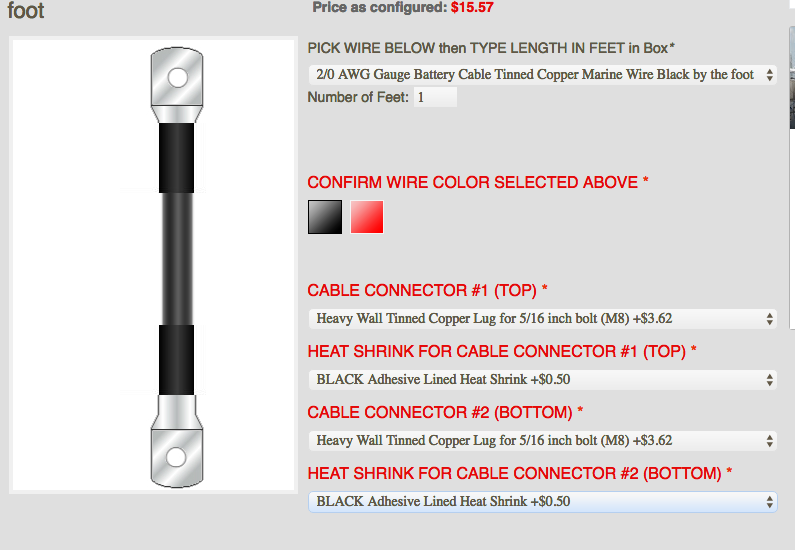

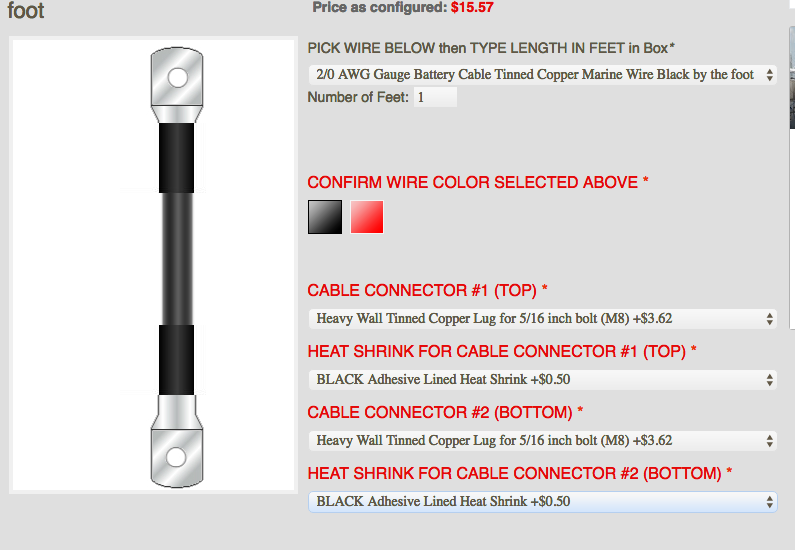

Time is ticking and I've got to get this done. My first question is about wire sizing for connecting my 2 12v batteries in parallel. genuinedealz.com was recommended in another thread but I'm not sure exactly what I need.

Here are my parts:

2 12v Batteries:

https://www.samsclub.com/sams/durac...rv-battery-group-size-31dtmagm/prod3590232.ip

Renogy 200w Solar Kit with PWM controller

Dometic CF-18 Fridge

MaxAir Fan

I was pricing out cables and I came up with about $60 just to wire them in parallel. That doesn't seem right.

I believe I have M8 lug connectors based off the specs from another website.

Here are my parts:

2 12v Batteries:

https://www.samsclub.com/sams/durac...rv-battery-group-size-31dtmagm/prod3590232.ip

Renogy 200w Solar Kit with PWM controller

Dometic CF-18 Fridge

MaxAir Fan

I was pricing out cables and I came up with about $60 just to wire them in parallel. That doesn't seem right.

I believe I have M8 lug connectors based off the specs from another website.