I'm making window screens for the minivan and have learned a few things.

After several trips to both Home Depot and Lowe's, I have found what works for me and what doesn't. Skeeter Beaters are overpriced and not strong enough for me, the over the door sleeve type mesh is not sized for my minivan. DIY to the rescue!

Buy the premium NoSeeUm mesh. The more open weave cheaper material lets in critters you don't want. One roll is plenty. Don't skimp on magnets, and don't use the flimsy flexible magnets. Go ahead and buy the more expensive and better quality rare earth neodymium magnets. The ceramic magnets are just okay. That must be what Skeeter Beater used, the "pull weight" is maybe 2 lbs. The "rare earth" neodymium is more like 5-8lbs.

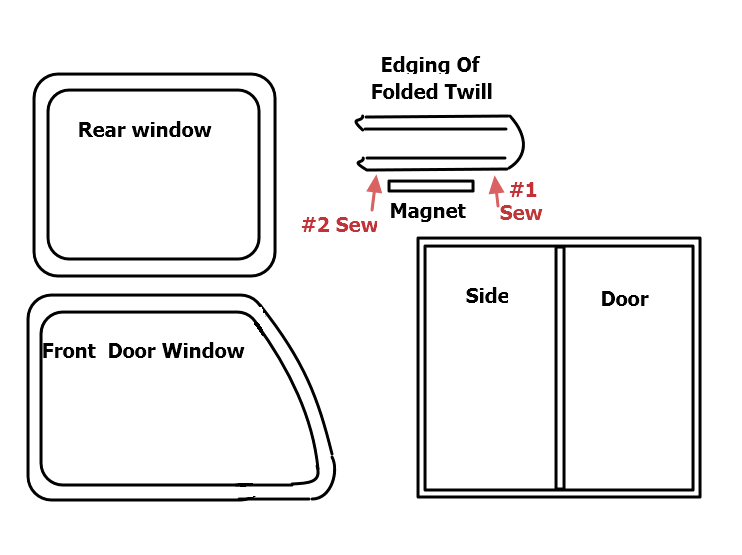

Lay the screen over the outside of the window, trim and adjust with a generous overlay. This makes for a better fit over rain deflectors, side mirrors and door handles. My minivan has dual sliding doors with 3 carrier brackets each that prohibit a two-sided fit. Plus that is really a waste of material when using the NoSeeUm mesh. Affix magnets and mark locations. I used at least 6 size 1/2" magnets on each of the sliding side door Windows, size 1/4" across the top of the front windows with the 1/2" magnets on the lower part.

I couldn't figure out how to screen off the rear quarter vent Windows without interfering with the door slides, so I opted to leave them alone. If I affixed screen from inside, there would be a layer of adhesive that would annoy me later. That's a shame, because I can open them manually, the two front and two side windows are power windows. But I decided that I'd rather be able to open the side door than the rearmost window. The rain deflectors allow me to keep the windows partially open no matter what the weather decides to do. Enough material is leftover for me to rethink this later.

Sewing in magnets messes up the feed dog and the bobbin on the machine. Too frustrating. If you elect to sew, mark the material with chalk and make magnet pockets, the after inserting magnets hand sew them closed. I got so frustrated with this I went with the more rigid Gorilla tape.

Do not use my good scissors on Gorilla tape. The blade of an exacto knife works well and doesn't gunk up my good scissors. I used a small craft roller to smush the tape to the mesh, and doubled the tape so the adhesive doesn't bleed through the mesh where instead it can stick to itself.

Mosquitoes carry disease like Zika and encephalitis, deer ticks cause Lyme disease and I am allergic to bees, wasps, etc. After getting sick earlier this summer when Mylan decided to make the EpiPen cost as much as 3 months' groceries, keeping bugs away from me is a very high priority.

Feedback?

After several trips to both Home Depot and Lowe's, I have found what works for me and what doesn't. Skeeter Beaters are overpriced and not strong enough for me, the over the door sleeve type mesh is not sized for my minivan. DIY to the rescue!

Buy the premium NoSeeUm mesh. The more open weave cheaper material lets in critters you don't want. One roll is plenty. Don't skimp on magnets, and don't use the flimsy flexible magnets. Go ahead and buy the more expensive and better quality rare earth neodymium magnets. The ceramic magnets are just okay. That must be what Skeeter Beater used, the "pull weight" is maybe 2 lbs. The "rare earth" neodymium is more like 5-8lbs.

Lay the screen over the outside of the window, trim and adjust with a generous overlay. This makes for a better fit over rain deflectors, side mirrors and door handles. My minivan has dual sliding doors with 3 carrier brackets each that prohibit a two-sided fit. Plus that is really a waste of material when using the NoSeeUm mesh. Affix magnets and mark locations. I used at least 6 size 1/2" magnets on each of the sliding side door Windows, size 1/4" across the top of the front windows with the 1/2" magnets on the lower part.

I couldn't figure out how to screen off the rear quarter vent Windows without interfering with the door slides, so I opted to leave them alone. If I affixed screen from inside, there would be a layer of adhesive that would annoy me later. That's a shame, because I can open them manually, the two front and two side windows are power windows. But I decided that I'd rather be able to open the side door than the rearmost window. The rain deflectors allow me to keep the windows partially open no matter what the weather decides to do. Enough material is leftover for me to rethink this later.

Sewing in magnets messes up the feed dog and the bobbin on the machine. Too frustrating. If you elect to sew, mark the material with chalk and make magnet pockets, the after inserting magnets hand sew them closed. I got so frustrated with this I went with the more rigid Gorilla tape.

Do not use my good scissors on Gorilla tape. The blade of an exacto knife works well and doesn't gunk up my good scissors. I used a small craft roller to smush the tape to the mesh, and doubled the tape so the adhesive doesn't bleed through the mesh where instead it can stick to itself.

Mosquitoes carry disease like Zika and encephalitis, deer ticks cause Lyme disease and I am allergic to bees, wasps, etc. After getting sick earlier this summer when Mylan decided to make the EpiPen cost as much as 3 months' groceries, keeping bugs away from me is a very high priority.

Feedback?