frater secessus

Well-known member

I was thinking about how common 100W Renogy panels are (both mono and poly) and how to extract maximum power from them with PWM controllers.

Short version

Longer version

Here are the ones I am talking about:

http://img.mousetrap.net/misc/100D__54543.1503503640.1280.1280__38558.1503694532.500.750.jpg

http://img.mousetrap.net/misc/100D__54543.1503503640.1280.1280__38558.1503694532.500.750.jpghttp://img.mousetrap.net/misc/RNG-100P-7__71447.1454451631.500.750.jpg

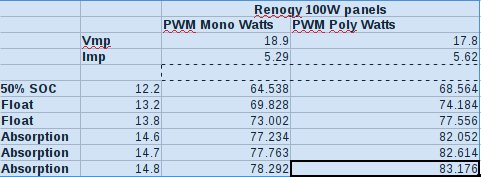

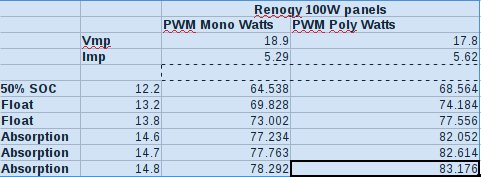

Here is some math on their lab output at various setpoints:

In actual ambient temperatures the poly panel Vmp falls to 14.8v at 103.1F degrees. The mono panel Vmp falls to 14.8v at 136F.

I used the temperature coefficient of VoC to calculate the panel temperature required to drop each panels' Vmp to 14.8v. Then I used this calculator to map panel temps to ambient temps.

Raising float from 13.2v to 14.6v for AGM yields 10.6% more power.

Raising float from 13.8v to 14.6v for AGM yields 5.8% more power.

Raising float from 13.2v to 14.8v for AGM yields 12.1% more power.

Raising float from 13.8v to 14.8v for AGM yields 7.25% more power.

Related: PWM vs. PPT power breakeven point

In the worst case for ppt (nominal 12v panels, high ambient temps and Vabs 14.8v ), a 95% efficient PPT controller would outperform PWM on poly until 96.53F ambient and mono until 127.4F ambient. At those temps PPT would still continue to outperform PWM in Bulk and normal Float (ie Vfloat < Vabs). Cost/benefit is not considered here, only power output.

Short version

- The Renogy 100W polycrystalline panel is a better fit for PWM controllers because power is generated at lower voltages.

- raising float from 13.2v to 13.8v on either panel will increase power output by 4.5%

- setting float voltage to absorption voltage per sternwake will increase power output from either panel between 6-12%

- PWM starts to meet MPPT output on poly when ambient temps >97F

Longer version

Here are the ones I am talking about:

http://img.mousetrap.net/misc/100D__54543.1503503640.1280.1280__38558.1503694532.500.750.jpg

http://img.mousetrap.net/misc/100D__54543.1503503640.1280.1280__38558.1503694532.500.750.jpghttp://img.mousetrap.net/misc/RNG-100P-7__71447.1454451631.500.750.jpg

Here is some math on their lab output at various setpoints:

In actual ambient temperatures the poly panel Vmp falls to 14.8v at 103.1F degrees. The mono panel Vmp falls to 14.8v at 136F.

I used the temperature coefficient of VoC to calculate the panel temperature required to drop each panels' Vmp to 14.8v. Then I used this calculator to map panel temps to ambient temps.

Raising float from 13.2v to 14.6v for AGM yields 10.6% more power.

Raising float from 13.8v to 14.6v for AGM yields 5.8% more power.

Raising float from 13.2v to 14.8v for AGM yields 12.1% more power.

Raising float from 13.8v to 14.8v for AGM yields 7.25% more power.

Related: PWM vs. PPT power breakeven point

In the worst case for ppt (nominal 12v panels, high ambient temps and Vabs 14.8v ), a 95% efficient PPT controller would outperform PWM on poly until 96.53F ambient and mono until 127.4F ambient. At those temps PPT would still continue to outperform PWM in Bulk and normal Float (ie Vfloat < Vabs). Cost/benefit is not considered here, only power output.