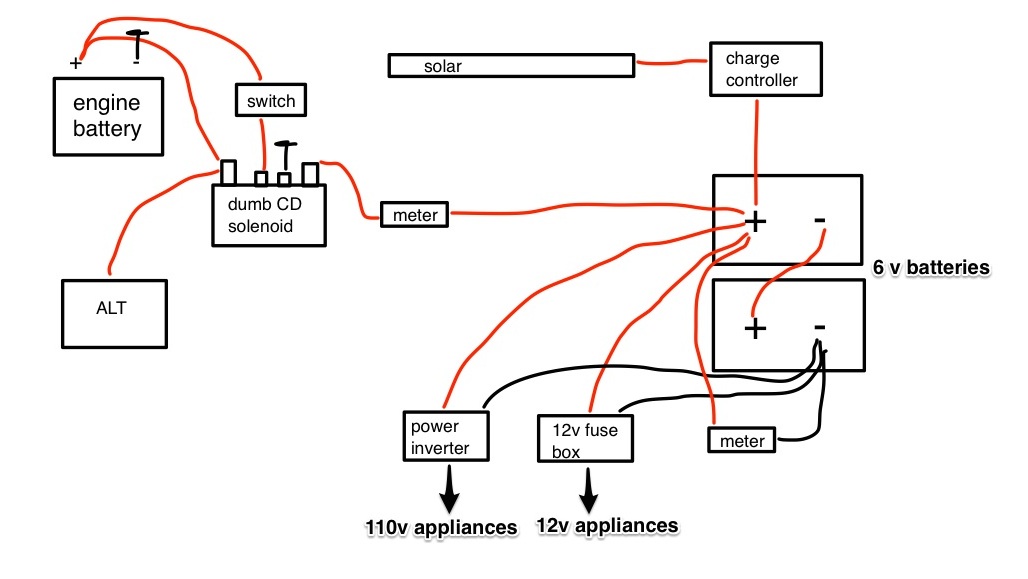

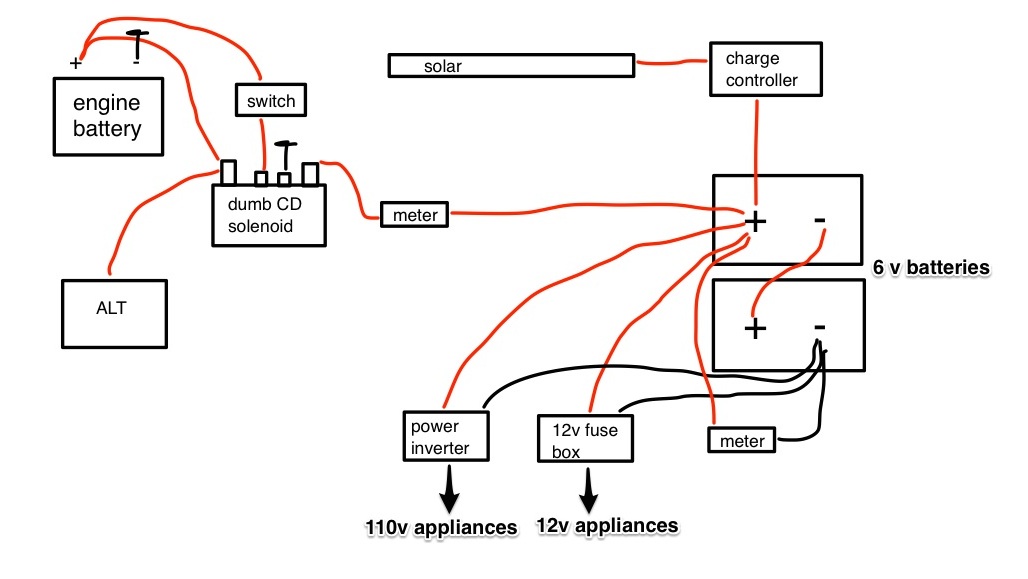

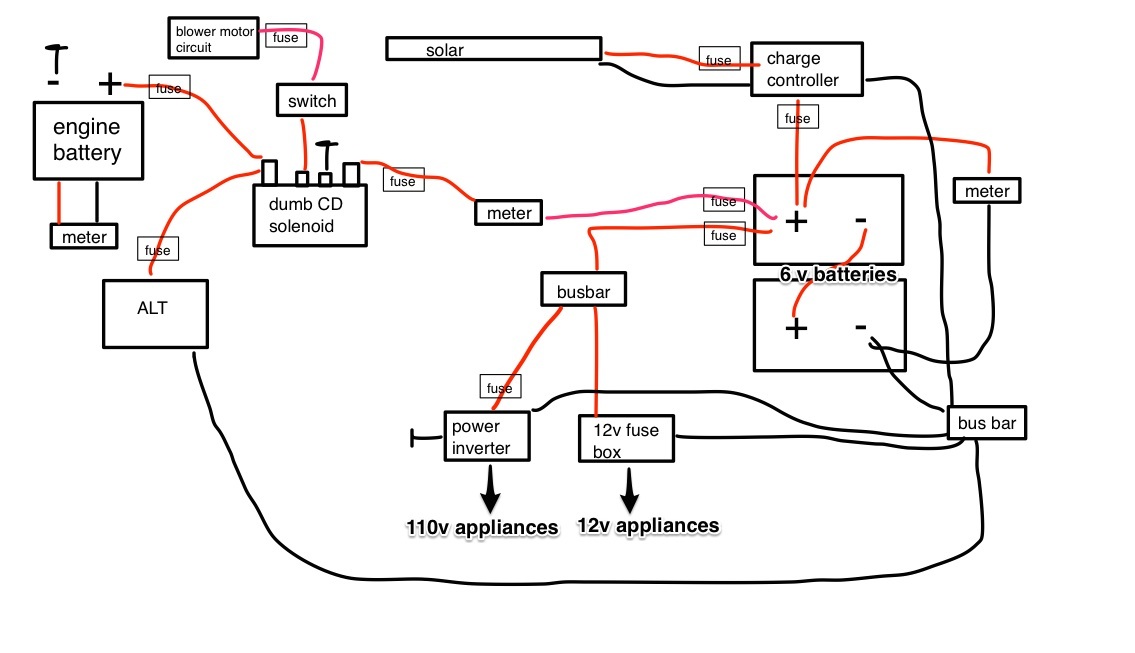

A Buss bar or a Buss stud is a common distribution point. So instead of wiring 12 individual circuits to the battery (-), one can run one fatter wire to the battery (-) from the Buss bar/Stud and all the thinner wires to the buss.

http://www.amazon.com/BB-4S-150A-DS...UTF8&qid=1403545222&sr=8-7&keywords=buss+stud

Full manual control of a dumb solenoid is easy. Just use a lighted toggle switch. One can also take the 12v(+) from the blower motor circuit and run it through the lighted toggle switch. This way, with the engine off, key out of the ignition the solenoid will be disconnected no matter the position the switch is left in.

This solenoid activation circuit needs to be fused too. Deciding where to pull the 12v for the activation circuit is what trips most people up. Full manual control is easy as one can just take 12v(+) from either battery(+), but pulling from the blower motor circuit requires a bit more. If the Vehicle uses ATC/ATO blade style fuses, then this product makes things easy:

http://www.amazon.com/Littelfuse-FH...1403545563&sr=8-1&keywords=ATC+ATO+add+a+fuse

Just plug it into the blower motor circuit and use the extra feed to run to the lighted toggle switch.

I have glass barrel type fuses from Dodge, and will admit to an improper crushing of stranded wire into the fuse holder itself, but for my aftermarket tachometer. I don't employ solenoids for battery isolation in my Van

If one does not want to crush stranded wire under a glass fuse, and does not have the ATC fuse holders from the factory, and does not have the skills to tap the blower motor circuit wire properly, then the following product can be used.

Let me state I think this is a bad idea. I bring it up only to help the gears click into place about what is needed to tap into an existing circuit.

http://www.amazon.com/Install-Bay-3...=UTF8&qid=1403546015&sr=8-1&keywords=wire+tap

When snapped over a wire, this device pierces the insulation and touches the wire stranding. It can also break some stranding and cause a point of resistance. The former owner of my Van used these to wire in a trailer harness and every tap severed half the wire strands, and caused serious brake light and signal light issues until I removed the sections of wires he used the products on.

The Blower motor circuit is usually fused at 20 or 25 amps and uses 10 or 12 awg wire, making the above product an extremely bad idea for tapping into the circuit.

Here is an example of my tapping into a wire( 2 wires actually), without having to cut the original wiring.

Carefully strip the insulation for about 3/4 of an inch in the middle of the wire. Make sure not to sever any stranding. Using an Awl or similar tool, open up a hole in the center of the stranded wire. Poke the New wire for the additional circuit through this hole, and wrap it around the other wire.

I soldered mine after the fact, and then used several layers of liquid electrical tape. One can forgo the soldering since the space to do so will be tight, and use electrical tape( quality) and use some small Zip ties to hold the new wire to the old to keep the stress off the area which was tapped.

One should do this with a fuse with pigtails. One of the Pigtails piercing the wire.

http://www.amazon.com/In-line-ACT-W...id=1403546899&sr=1-2&keywords=atc+fuse+holder

Here are some pics showing how I tapped my OEM alternator(+) wire to feed my nearby headlamp relays.

Hope this addresses the questions you asked in the PM