HerrSuite

New member

Hi all! I'm working on a step van, and I've landed here as close a place to 'my people' I can find. My project is a little unusual - not trying to build a space to live but a space to work. I'm a full-time muralist, and the goal is a mobile studio that I can work inside of to do design work, then take to a job site and work out of like a work truck to paint murals. My sights are set on 'simple' and 'functional'.

Okay, so I'm 5 months into wrestling with this project, and I'd love to share and get some feedback. I've never done any vehicle work before at all, and have very minimal building experience. I've been detailing my whole process on my blog (see signature, or go to the first post about the step van itself), but I'll put the highlights up here. I've also posted them on skoolie.net, if any of y'all are on both :

20' long 1993 GMC Grumman Olsen P-35 Step-Van

Cute, right? Those are the 'before' pics from December. Since then I've mostly been planning and fretting, but I've also ripped out a lot of stuff. Gone are the shelves and metal grid divider behind the driver's seat, gross seat cover, the e-track on either side, and the whole back door and half of the tracks for it (the rest were welded on and not in the way enough to worry about).

Oh yeah, I also released a herd of children with spray paint at it I'm going to be painting all over it anyway, so why not? (There are a lot of reasons why not, I'm already finding, but what's done is done)

I'm going to be painting all over it anyway, so why not? (There are a lot of reasons why not, I'm already finding, but what's done is done)

So my plans now are as follows:

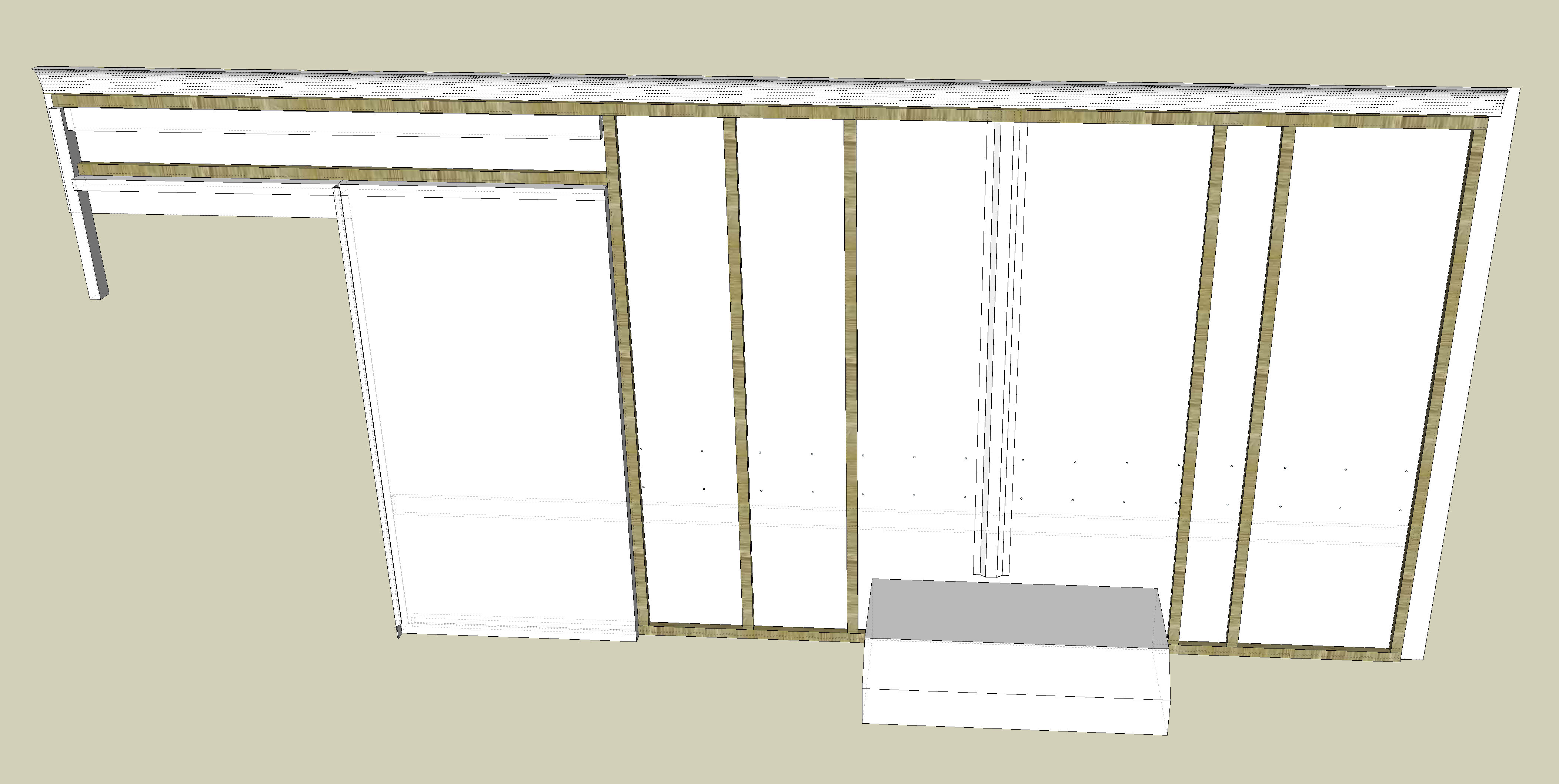

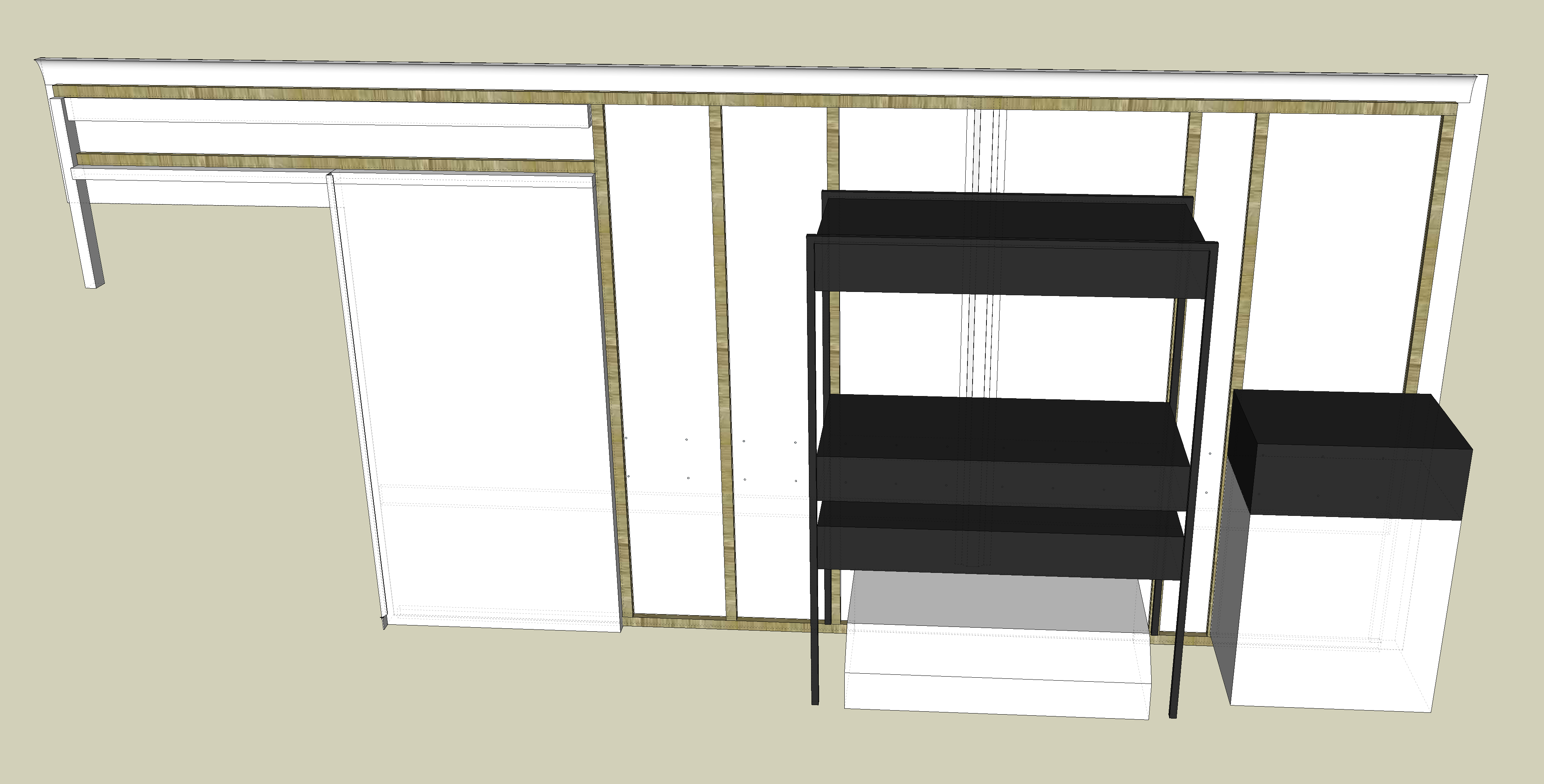

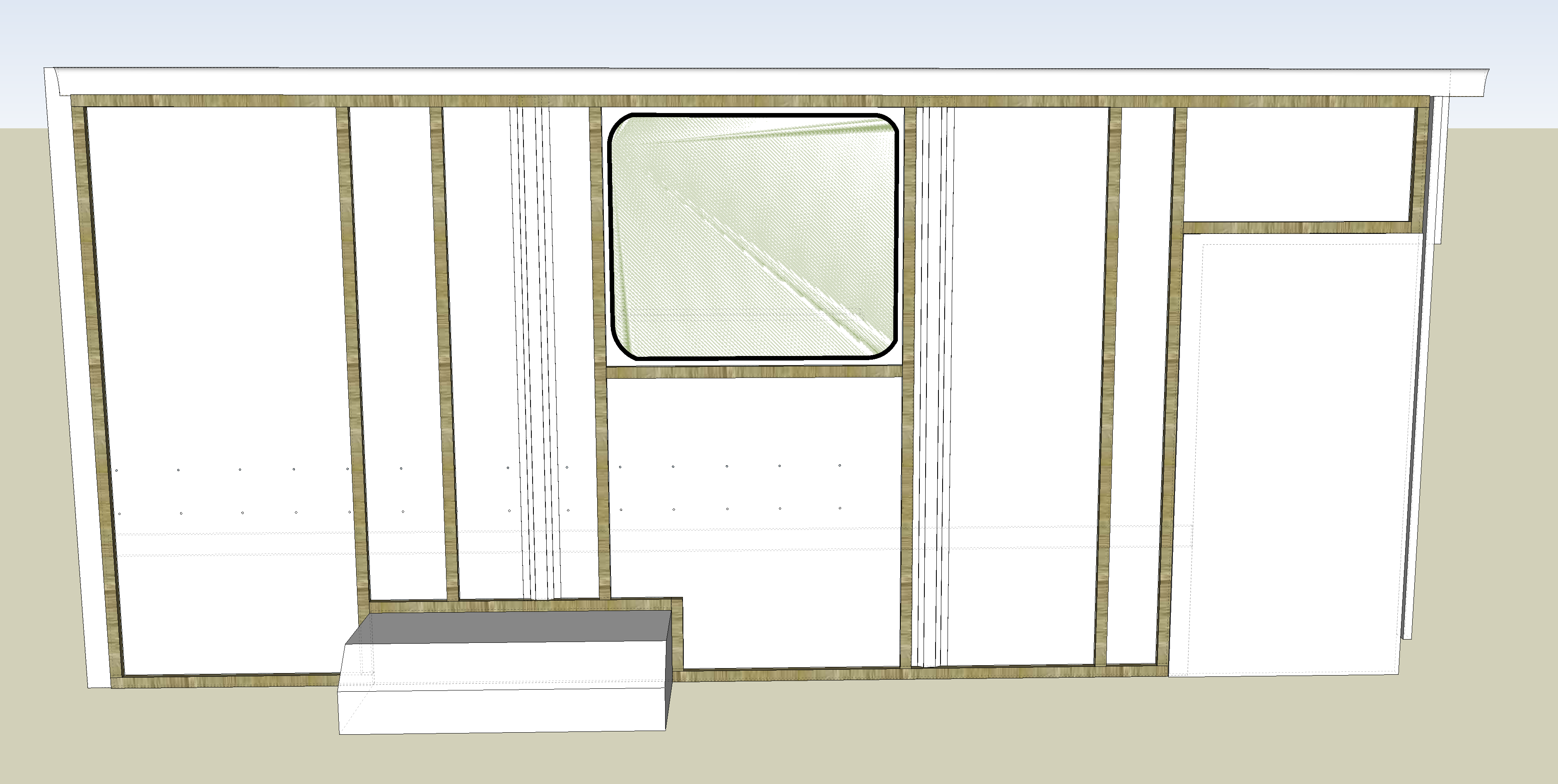

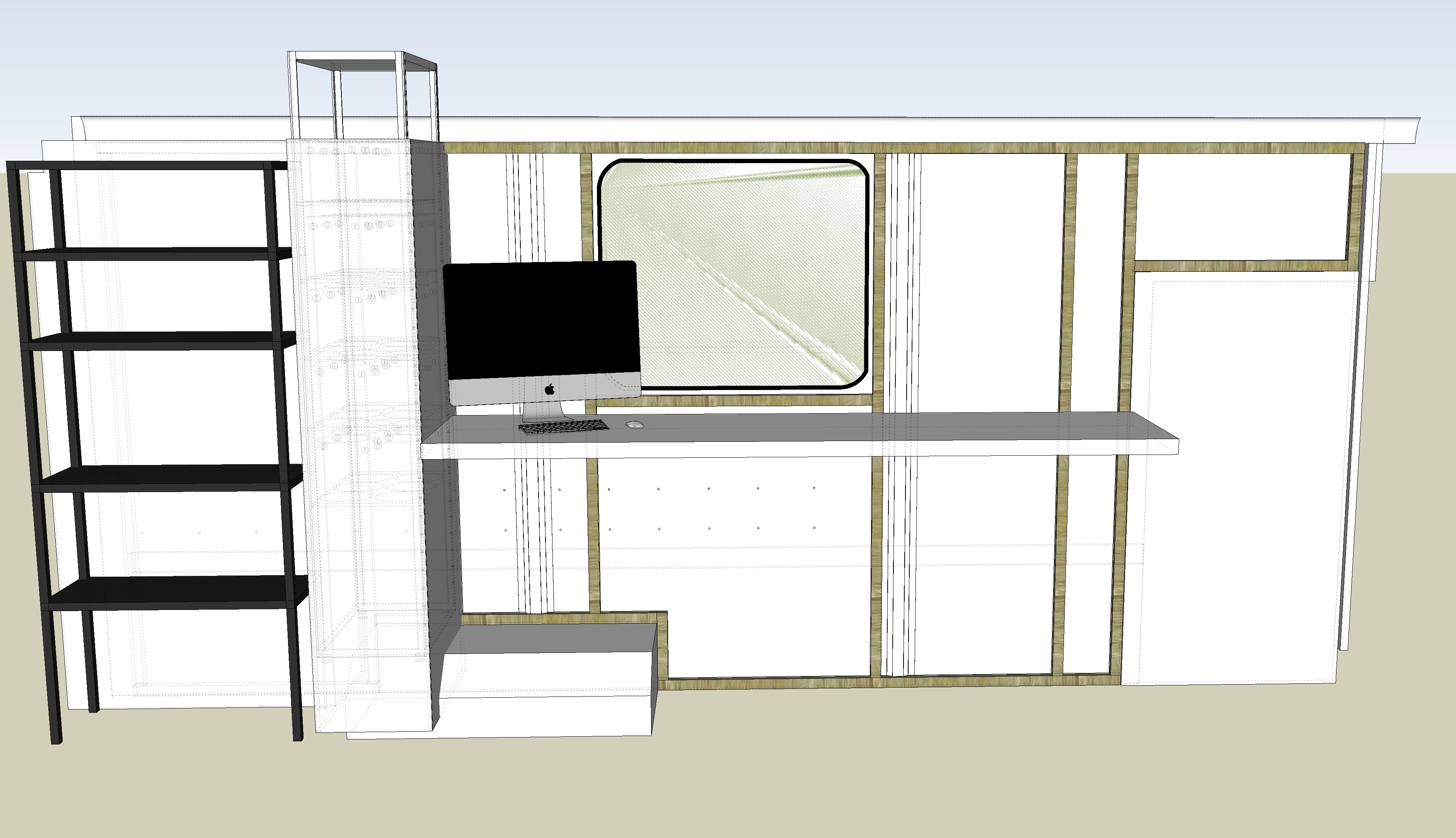

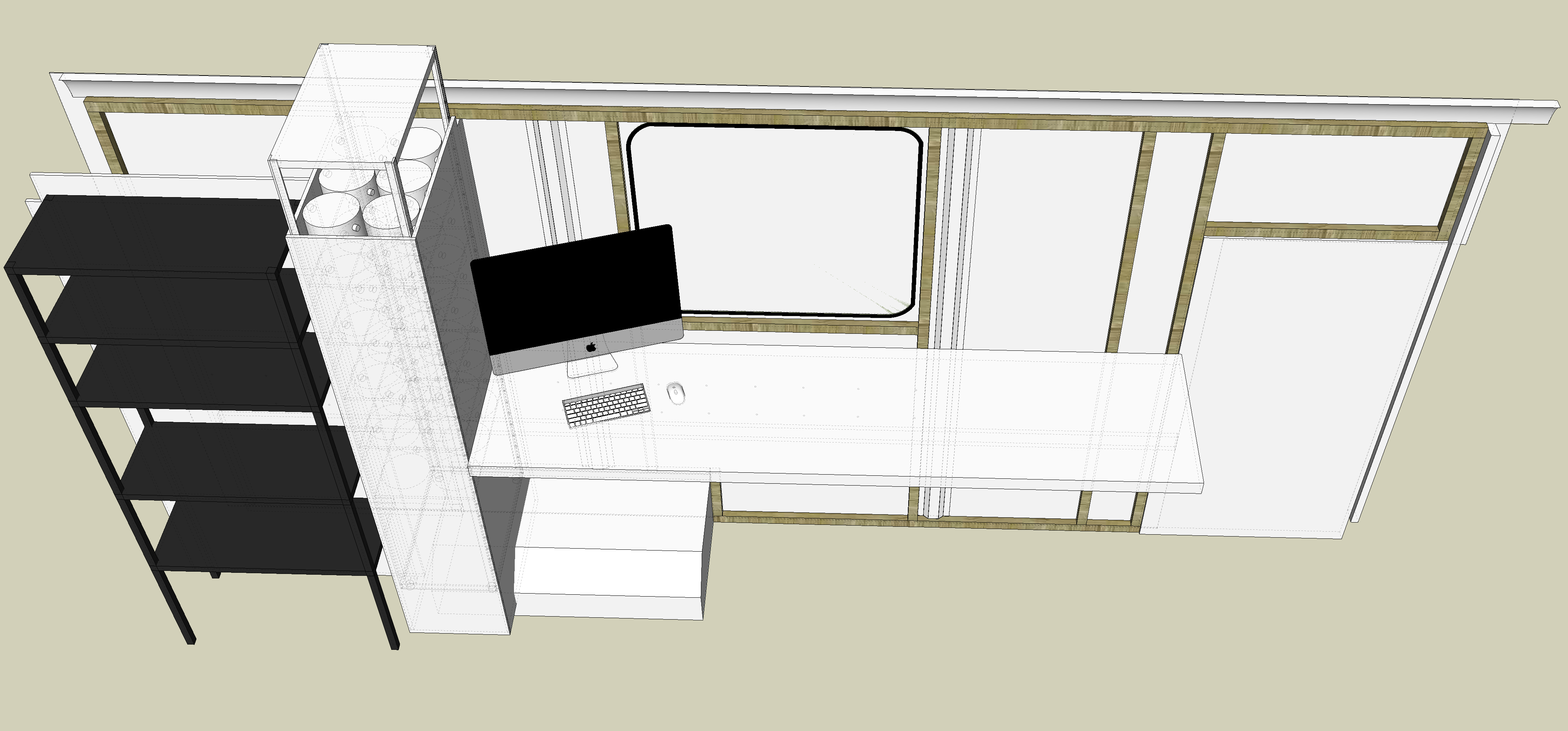

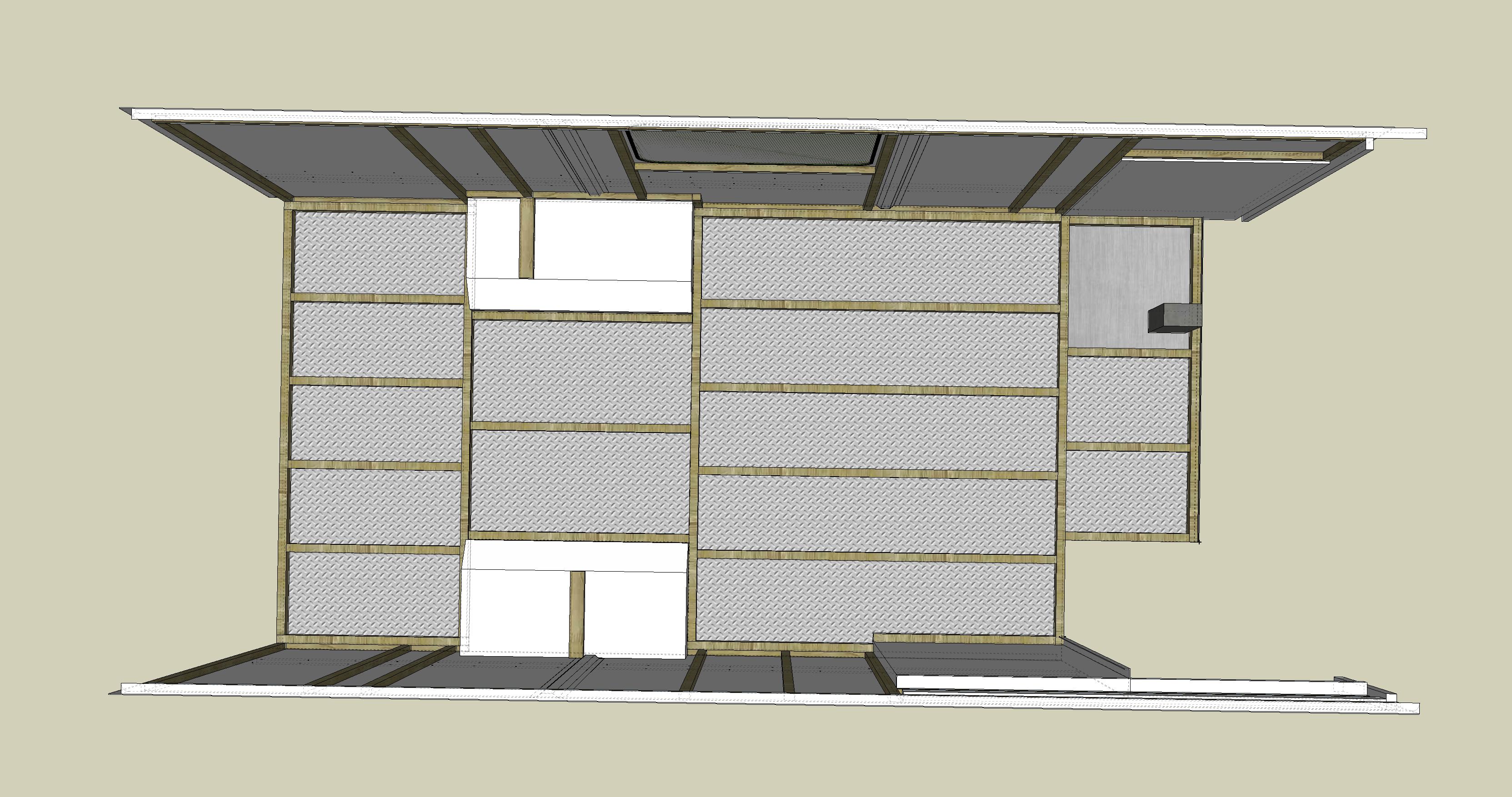

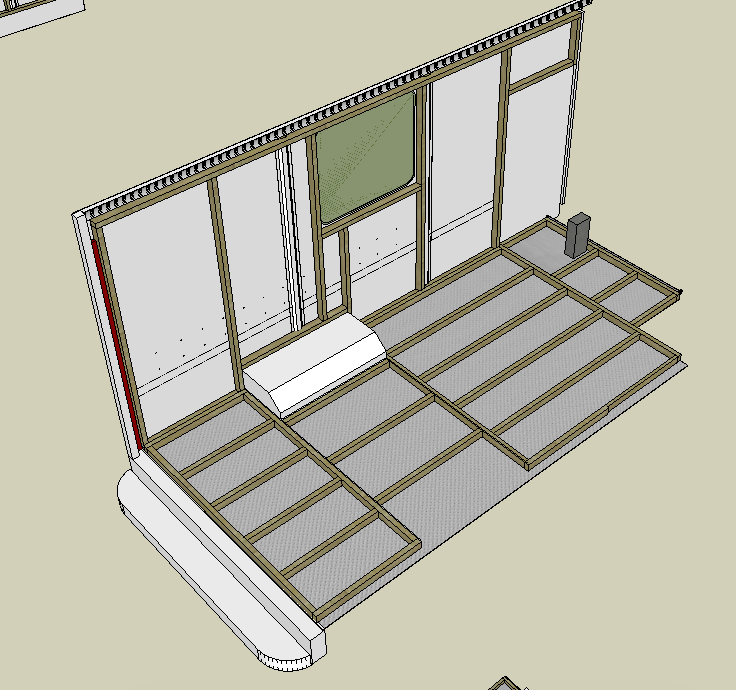

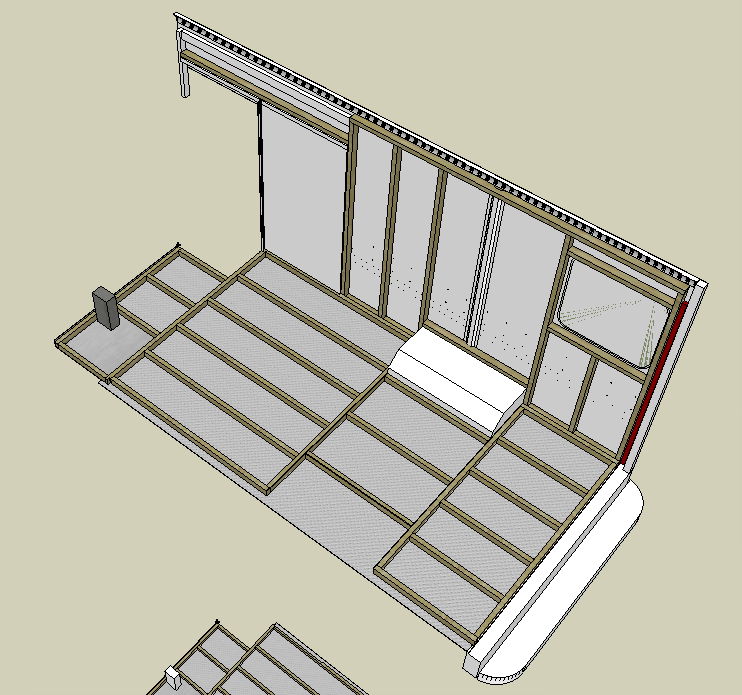

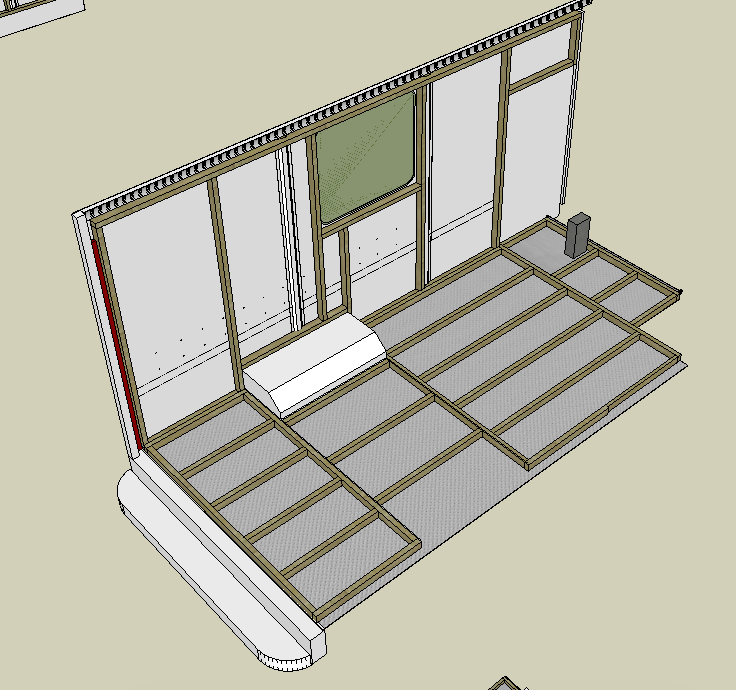

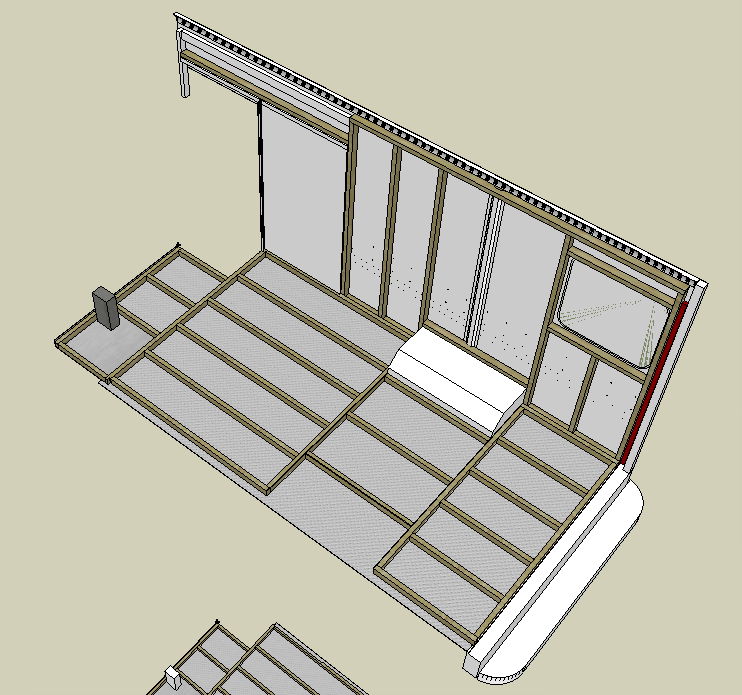

A sketchup of the building plan so far (rough sketchup of interior later coming soon)

Thanks for any advice or feedback! Tried to keep this light, so there's a lot of plans/ideas I haven't mentioned, but I'll update for sure.

Okay, so I'm 5 months into wrestling with this project, and I'd love to share and get some feedback. I've never done any vehicle work before at all, and have very minimal building experience. I've been detailing my whole process on my blog (see signature, or go to the first post about the step van itself), but I'll put the highlights up here. I've also posted them on skoolie.net, if any of y'all are on both :

20' long 1993 GMC Grumman Olsen P-35 Step-Van

- 4,000 lbs. empty

- 253,000 original miles

- 8-cylinder 350 engine (the second in it)

- 20' from bumper to bumper, 11'2" ground to roof, 6'11" wide

- 6'10" tall and wide on the inside, 12' cargo space

- garage-style door and double rear wheels (boo)

- radio, a/c, heat

- 1 door (passenger side)

- broken gas gauge

- chipped front windshield, 1 cracked side mirror

- brand new front tires

- Needed work on the steering column, rear axle and brakes, and exhaust system in order to pass state inspection.

Cute, right? Those are the 'before' pics from December. Since then I've mostly been planning and fretting, but I've also ripped out a lot of stuff. Gone are the shelves and metal grid divider behind the driver's seat, gross seat cover, the e-track on either side, and the whole back door and half of the tracks for it (the rest were welded on and not in the way enough to worry about).

Oh yeah, I also released a herd of children with spray paint at it

So my plans now are as follows:

- cut two windows into the walls in the back (it didn't come with the luxury of school bus windows!) I already have the glass, salvaged from a 1992, and have outlined the placement for them on the walls themselves. Just have to drop it off at the auto glass place next week.

- frame out the interior walls/floor/ceiling to hold insulation and sheathing. several questions here - obviously i won't be framing to code, so what distances should I actually worry about? and what size lumber for framing? (planned for 2x3's right now, but I feel like I can go smaller) what kind of sheathing that won't offgas formaldehyde from being next to the sun-heated aluminum wall? I know my thickest insulation should be in the floor and ceiling, but how thick?

- buy and install solar system to power desktop computer, a/c, lights, various small chargers and electronics

- find out if I can buy a mini-split small enough for this size of space - I've been told I can find one but I'm not totally convinced it'll work

A sketchup of the building plan so far (rough sketchup of interior later coming soon)

Thanks for any advice or feedback! Tried to keep this light, so there's a lot of plans/ideas I haven't mentioned, but I'll update for sure.