Yes, in this instance of wiring up a house battery, consider the alternator charging circuit completely separate. Forget the starter solenoid completely for now.

Regarding performance of this house battery charging system, its efficacy in charging batteries to as high a state of charge as possible, as quick as possible, the diagram above is lacking.

Where it says 'factory wiring' this is an electrical bottleneck that limits current flow to a house battery depleted below 80% charged. Most vehicles factory alternator circuit is sized only large enough 'just to get by' type of logic. as the manufacturer's didn't say one day,

"Hey, incase somebody in 20 years wants to convert this into a campervan and cycle additional batteries deeply, lets make the alternator circuit wire 2awg and use a really fat ground wire to the engine too!!"

No the conversation went more like. "What is the absolute minimum thickness cable can we get away with?

Answer "8awg"

--- Sure we can't use 10?

"no 8awg is in the very edge of powering all vehicle loads and should be able to keep a nearly fully charged starting battery, nearly fully charged.

Sigh, well use 8awg then, but we will have to cut corners elsewhere.

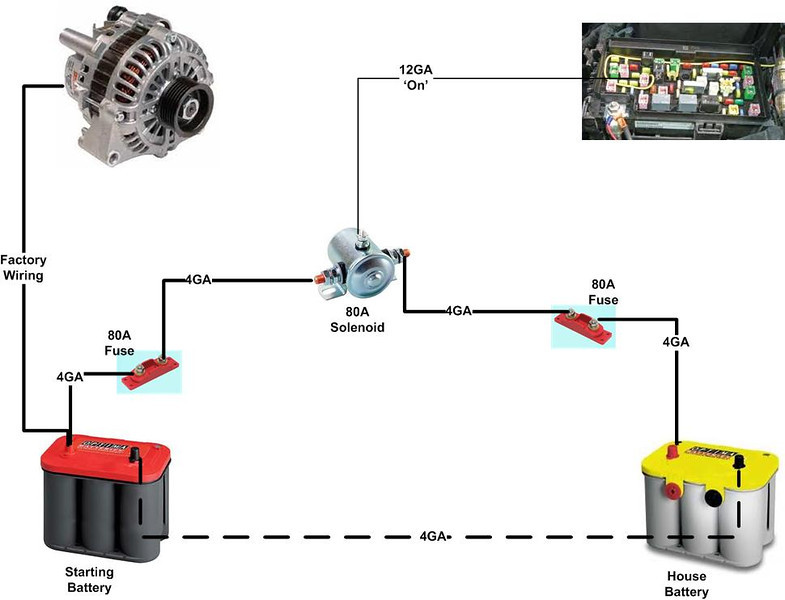

So, refer back to that diagram above and see the (+) factory wiring goes from alternator to engine battery, then to solenoid?

Bypass it. Hook solenoid directly to alternator(+) instead of engine battery (+).

4 awg at alternator---> 80 amp fuse-> 4awg----------------> 120 amp CDsolenoid------------------>-80 amp fuse--->house battery(+).

That is the (+) side of the circuit

Regarding the return ground path....

Also one can ground house battery directly to nearest frame, OR directly to engine battery, OR directly to alternator mounting bolt or a (-) Alt stud if one exists on the alternator. If one grounds directly to frame nearby house battery, then they should also ground the alternator to the frame, or increase the thickness of the wire from engine battery to engine block, for better performance, or just add another in parallel.

This wiring route will significantly increase charge rate into depleted battery upto 80% charged, but not really help speed things up from 80 to 100% which is basically 4 hours minimum, no matter the charging source.

It depends on the voltage your vehicle's voltage regulator allows.

But the VR will hopefully see the increased alternator field current required to achieve maximum voltage, and allow it to be held longer. Vehicles VR's are wacky things, also not designed to consider recharging additional batteries. Better vehicle voltage regulation can be accomplished but is a different topic.

This upgraded alternator charge circuit will also increase the load on the alternator, heating it more, shortening its lifespan to some unknown degree.

The danger lies mostly with vehicle alternators which can produce high amperage when hot and at idle speeds, and the user decides to idle to recharge a very hungry depleted battery which can ask for 60+ amps.

The slow spinning alternator fan cannot remove enough heat from it, and combine this with baking under the hood, can easily allow the alternator to exceed 220F and spend too much time in this temperature range/ danger zone.

When moving the higher rpms and air movement underhood significantly decreases alternator temperature, at least on my Van. Especially highway speeds. it can be maxed out and only 110F at 65mph, but pull off the freeway and idle at a traffic light and it can spike to 160F in a minute. Still collecting more data on this.

So One 'could' intentionally reduce the load on the alternator by using thinner cabling and sacrifice better battery charging. if one's alternator is a huge PITA and expense to replace, then it makes no sense to overtax it trying to extend battery life, but making sure one has enough recharge occurring to power their Cpap overnight.

So there are performance options to consider, and the capability of any vehicle's charging system can be vastly different that of another brand/year so blanket statements are best avoided, but at the same time there are generally truths in this arena, with exceptions.

One thing also not yet mentioned is the rating of the vehicles alternator. This rating is earned in a laboratory with a cold alternator spinning fast and huge loads asking for everything the alternator can make over very thick copper cabling.

The '140 amp' rating means that is the absolute maximum it can ever hope to employ in ideal conditions, and only briefly.

What a higher amp rating really means to a vandweller is that the alternator is more likely to be able to shed the excess heat it will generate when asked to work really hard charging a depleted battery at its limits of amperage acceptance at the voltage allowed by the vehicles voltage regulator.

A higher rated alternator 'might' not be able to product any more amperage at idle speeds than its lower rated counterpart. I could pull up some graphs from Balmar showibng an example or two, but I've spent too much time writing this as is and will click submit no