FALCON

Well-known member

- Joined

- Mar 28, 2015

- Messages

- 500

- Reaction score

- 0

So I was just about to order four 100w Renogy solar panels last night, but I when I looked at the volts and amps they would produce, I didn't feel sure enough about what type of charge controller I would be buying and whether I should hold off on buying panels until I figure that out... With the big price differences between PWM and MPPT (at least for Tristars) I wanted to have a good idea which way to go.

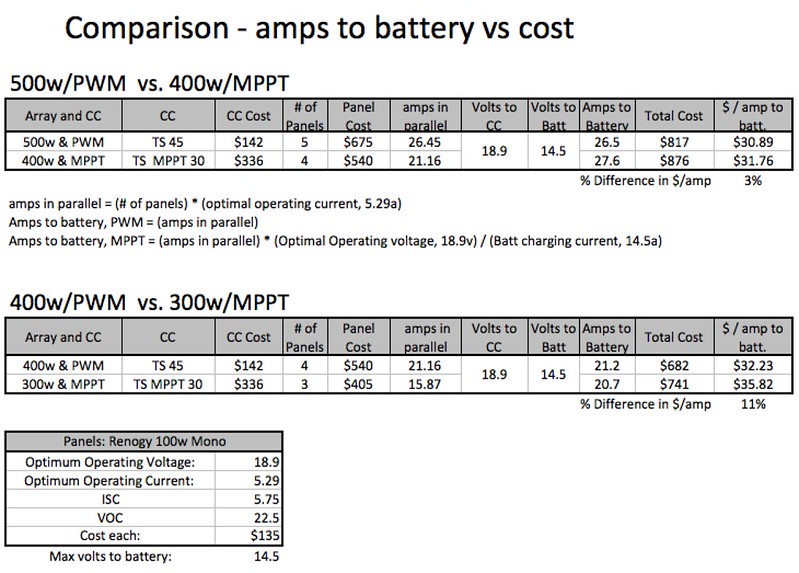

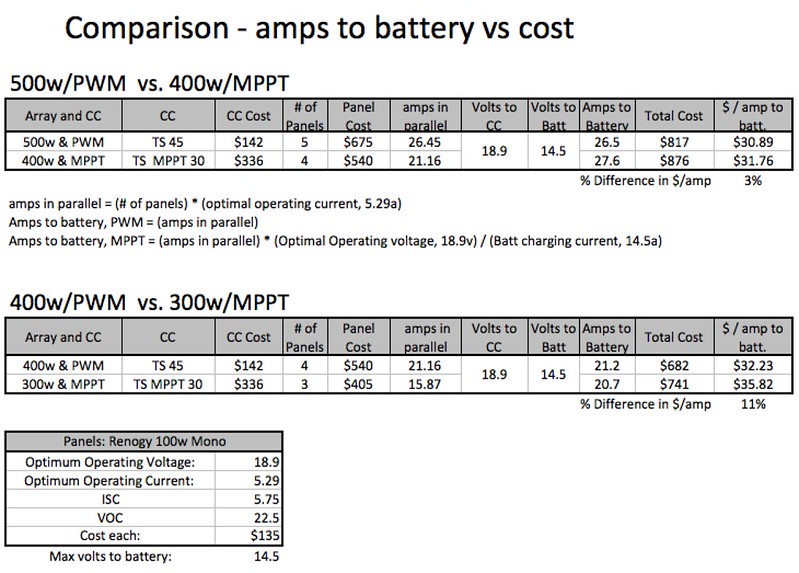

So today I did a little more reading on MPPT and PWM differences. I try to compare things in simple ways and the simplest way to me seems to be the resulting amps going into the battery considering the loss you get with a PWM compared to the voltage/amps conversion you get with an MPPT.

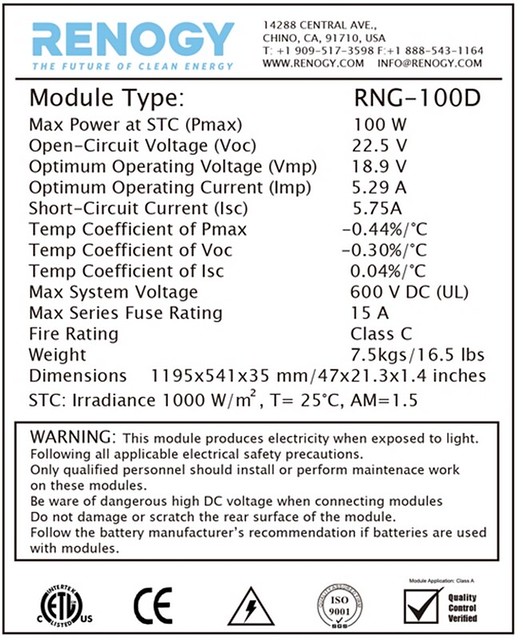

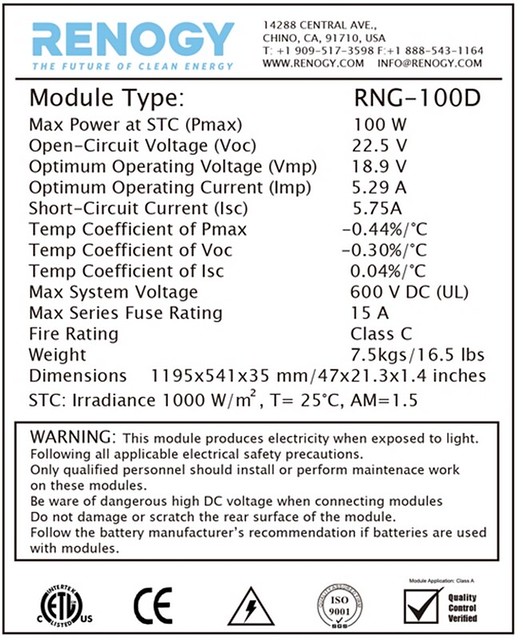

For this comparison, I'm looking at Renogy 100w Mono Panels:

And these charge controllers:

PWM: Morningstar Tristar PWM 45am. (TS-45)

MPPT: Morningstar Tristar MPPT 30amp (TS MPPT 30)

My power use calculations based off max expected power use (100Ah) and using 3.5 winter peak sun hours, with an MPPT CC, gave a required array wattage of 330 watts.

I'm just doing this cost calculation to see if there is a significant difference between using a PWM and more array wattage vs using an MPPT and less array wattage. I don't care whether is it dead on correct - just whether I'm using the right type of values and formulas for these calculations. Did I do the calculations the right way?

With my calculations, it doesn't look like the cost savings of using a PWM are worth the extra effort of having another panel on the roof (or, if I end up filling the roof space with panels for some reason - I believe an MPPT would allow me to get more energy from them into the batteries)

So today I did a little more reading on MPPT and PWM differences. I try to compare things in simple ways and the simplest way to me seems to be the resulting amps going into the battery considering the loss you get with a PWM compared to the voltage/amps conversion you get with an MPPT.

For this comparison, I'm looking at Renogy 100w Mono Panels:

And these charge controllers:

PWM: Morningstar Tristar PWM 45am. (TS-45)

MPPT: Morningstar Tristar MPPT 30amp (TS MPPT 30)

My power use calculations based off max expected power use (100Ah) and using 3.5 winter peak sun hours, with an MPPT CC, gave a required array wattage of 330 watts.

I'm just doing this cost calculation to see if there is a significant difference between using a PWM and more array wattage vs using an MPPT and less array wattage. I don't care whether is it dead on correct - just whether I'm using the right type of values and formulas for these calculations. Did I do the calculations the right way?

With my calculations, it doesn't look like the cost savings of using a PWM are worth the extra effort of having another panel on the roof (or, if I end up filling the roof space with panels for some reason - I believe an MPPT would allow me to get more energy from them into the batteries)