PlethoraOfGuns

Well-known member

Finally had a day or two without snow. Boy, what a winter.

[size=small]For those that are wondering, this is how you get the engine and transmission in and out of the van. Super easy with plenty of room to work with. Just need to remove the passenger seat.[/size]

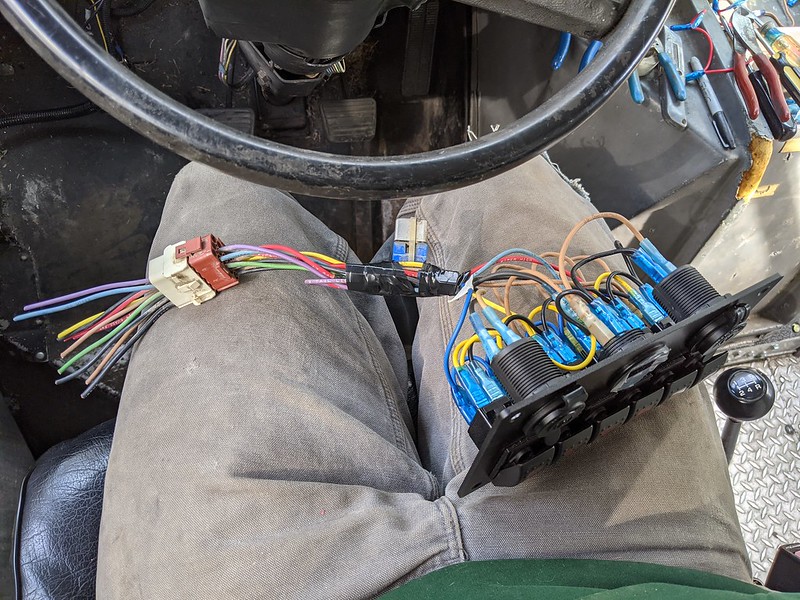

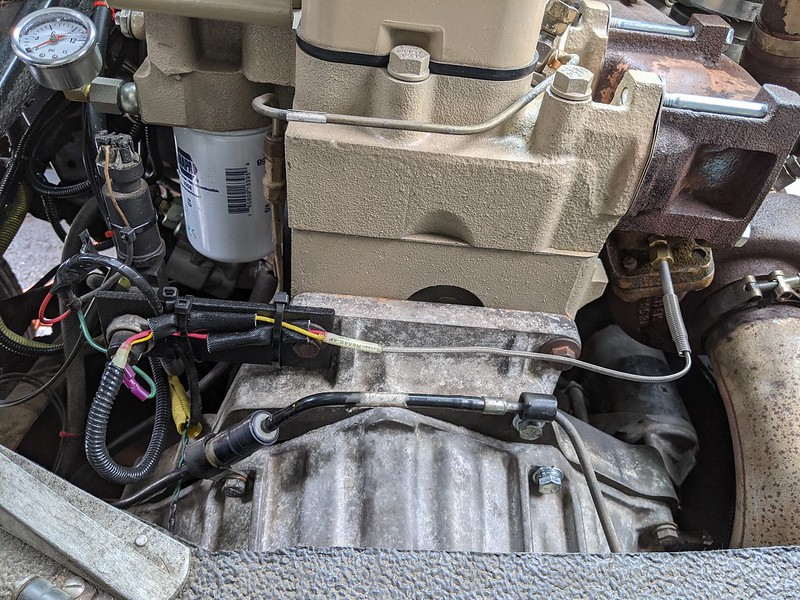

[size=small]Got everything hooked up. All the new sensors and things installed too. Can we talk about an amazing invention? They're called cable ties, so simple and so useful.[/size]

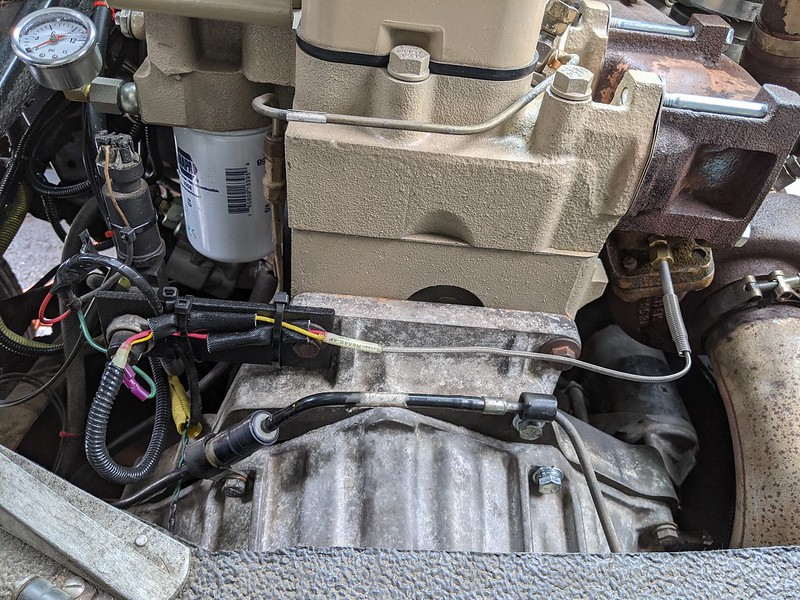

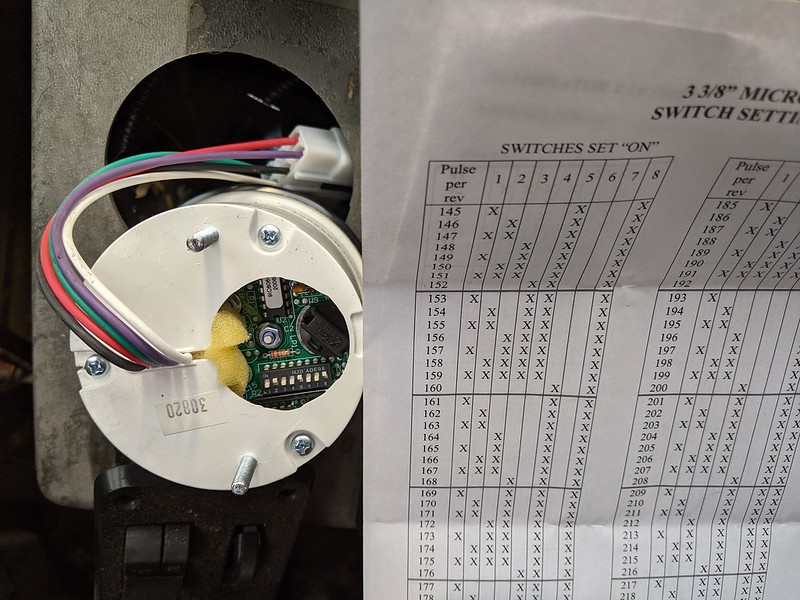

[size=small]A shot looking down at the the magnetic pickup sensor for the tachometer on the drivers side of the bellhousing. This one has me worried. Witchcraft is how it all works. We'll see if I casted the proper spells to make this one work.[/size]

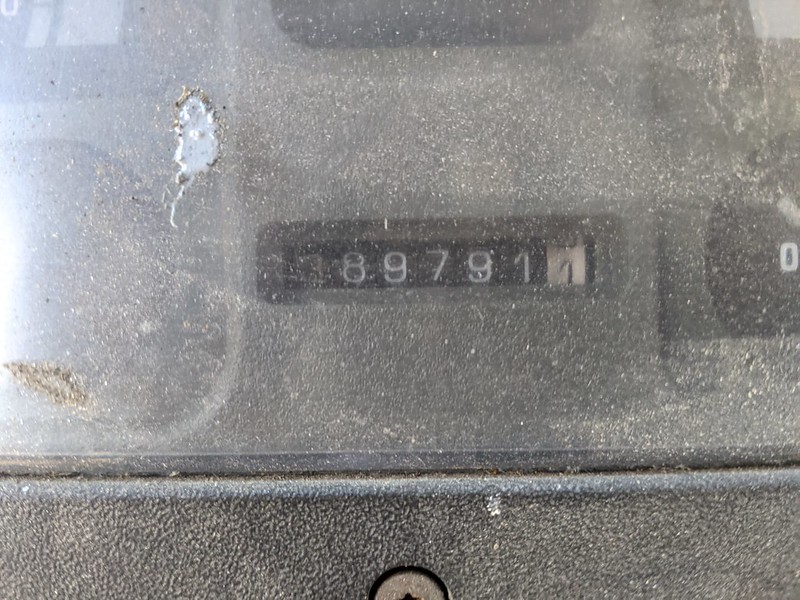

[size=small]Cut a hole in the dash for the tachometer. Found out why the floor heat wasn't working so great. Damn Tennessee rodents...[/size]

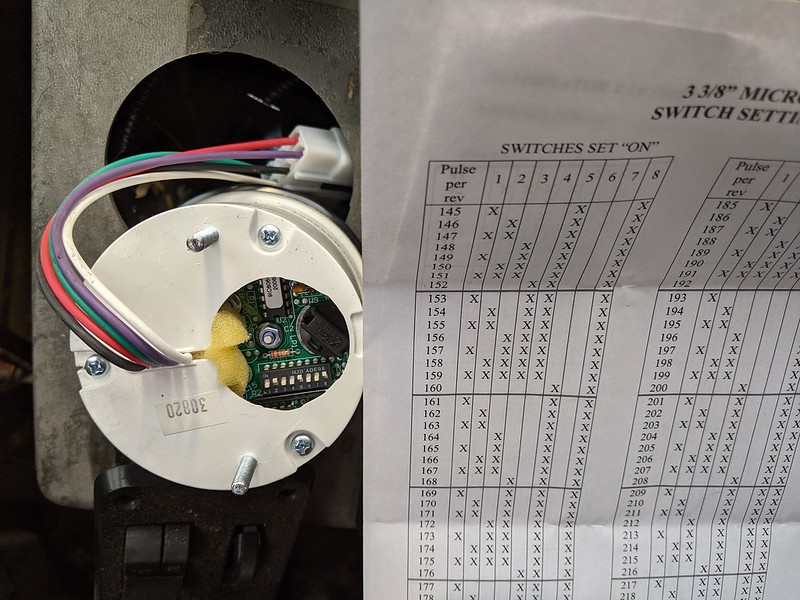

[size=small]Also for anyone curious about the spells to make this tachometer work with the magnetic pickup sensor.[/size]

And there we go. Four new gauges added and we're good to go. All power is good, hoses connected, fluids topped off, everything cable tied, turned the key and...

[size=small]For those that are wondering, this is how you get the engine and transmission in and out of the van. Super easy with plenty of room to work with. Just need to remove the passenger seat.[/size]

[size=small]Got everything hooked up. All the new sensors and things installed too. Can we talk about an amazing invention? They're called cable ties, so simple and so useful.[/size]

[size=small]A shot looking down at the the magnetic pickup sensor for the tachometer on the drivers side of the bellhousing. This one has me worried. Witchcraft is how it all works. We'll see if I casted the proper spells to make this one work.[/size]

[size=small]Cut a hole in the dash for the tachometer. Found out why the floor heat wasn't working so great. Damn Tennessee rodents...[/size]

[size=small]Also for anyone curious about the spells to make this tachometer work with the magnetic pickup sensor.[/size]

And there we go. Four new gauges added and we're good to go. All power is good, hoses connected, fluids topped off, everything cable tied, turned the key and...